Introduction

In a more digitized world, the real power of printed material cannot be ignored. Printing is a pillar of communication, trade, and artistic expression, and it is visible everywhere because of the books we read and the packaging that keeps our items safe. A practical knowledge of the various forms of printing is not only academic to the business, but it is also a practical requirement for designers, students, and creators. The skill to differentiate between different printing methods has a direct impact on the result of the projects, as it affects all aspects of budget and production time, visual quality, and brand awareness and recognition.

The history of printing is an account of human invention. Although early printing, such as woodblock printing, had existed for centuries before, the major turning point was reached in the 15th century with Johannes Gutenberg, and the printing press was invented. This brought a revolution in mass communication and preconditioned advanced methods of printing that we use nowadays. Selecting the right printing process would mean that the intent of a design is accurately captured on a physical surface, and this might either need the precision of a photograph or the dramatic effect of a promotional post. This guide will cover six major types of printing, which will give the clarity required to make informed decisions for any project.

Offset Printing: The Gold Standard for High-Volume Quality

Offset printing, or lithography printing, is one of the oldest printing methods. The technique is employed by using a printing plate that transfers the ink onto a rubber blanket, which then presses the image onto the substrate. Because of the indirect transfer, it provides very clean edges, smooth coverage, and consistent color reproduction over extended runs. Since the initial setup is expensive, it is optimal for high-volume work where per-unit printing costs can be amortized.

Pros

- ● Excellent, consistent image quality with sharp detail and accurate color.

- ● Economical for mass production; unit price decreases as volume increases.

- ● Compatible with many papers and coatings; supports large-format sheets.

- ● Durable process, excellent for professional print media standards.

Cons

- ● The extensive initial setup (plates, calibration) makes it unfeasible for small runs.

- ● Slower turnaround compared to digital printing.

- ● Skilled operators are needed, and the process consumes more energy, which can increase the environmental impact.

- ● Marketing collateral such as brochures, catalogs, and large format posters.

Applications

- ● Uniform quality at scale is required by the printing of newspapers, books, and magazines.

- ● Marketing collateral such as brochures, catalogs, and posters.

- ● High-volume custom packaging (e.g., folding cartons).

- ● Corporate stationery, annual reports, and brand materials require higher-quality finishes.

Digital Printing: Fast, Flexible, and Perfect for Small Batches

Digital printing removes the need for traditional printing plates, allowing for the direct transfer of images from a digital file onto paper, film, or other substrates. For this reason, it is one of the most flexible printing techniques. This method is particularly useful for short runs and for projects that require a quick turnaround. New methods such as UV printing and LED UV printing, and other developments in digital printing are useful in flexible packaging and other specialty applications, enabling brands to be more responsive with shorter campaigns.

Pros

- ● Ideal for on-demand jobs with little initial setup.

- ● Personalized marketing is possible with the support of variable data.

- ● Particularly with specialty inks, there is a notable advancement in color reproduction.

- ● There are multiple substrates, including paper, labels, and thin films.

- ● There are low printing costs for short projects.

Cons

- ●Reaching scale, offset printing becomes more cost-effective.

- ● For strict needs, there is a loss of resolution or durability in comparison to gravure or flexo.

- ● Very large, long runs or large-format jobs are not efficient.

- ● Some substrates need primers or coatings.

Applications

- ● Flyers, brochures, and business cards are produced quickly.

- ● For short runs, various flexible packaging materials are used, including pouches, shrink sleeves, and laminated films.

- ● Variable-data direct mail, tickets, and barcoded labels.

- ● Niche custom packaging or trial campaigns in limited quantities.

Flexography: The Packaging Industry’s Favorite Choice

Flexographic printing, or flexo printing, is a technique in which a flexible relief plate is used to apply liquid ink directly onto different materials like paper, films, foils, and even corrugated board. It is one of the most versatile printing methods, as it can print on uneven surfaces and also runs continuously on a roll. For this reason, it became the backbone of the packaging industry.

Pros

- ● High-speed production; suitable for very long runs.

- ● Works across a wide range of substrates, including flexible packaging.

- ● Quick-drying inks support fast finishing and converting.

- ● More economical setup than gravure for mid-to-high volumes.

Cons

- ● Lower image resolution than offset printing or gravure.

- ● Initial setup still requires plate-making.

- ● Limited performance with very fine lines or photographic detail.

- ● Ink-substrate chemical interaction can affect consistency.

Applications

- ● Food wrappers, snack bags, and laminated pouches.

- ● Corrugated boxes, folding cartons, and shipping packaging.

- ● Pressure-sensitive labels, envelopes, and wallpaper.

- ● Durable and speedy. Everyday consumer goods packaging requires these features.

Screen Printing: Bold Colors on Almost Any Surface

This method of printing involves pushing liquid ink through a mesh screen stencil onto different surfaces. Differing from other forms of printing technology, this technique is a great option that uses thick layers of ink, which in turn creates designs that have a strong opacity and durability. The ability to print on flat and uneven surfaces makes this technique very versatile, especially when it comes to promotional and specialty products.

Pros

- ● Bright, vivid colors and strong, saturated colors.

- ● Durable prints that are sunlight and abrasion resistant.

- ● Compatible with a diverse range of materials.

- ● Ideal for large designs such as banners and signage.

Cons

- ● Production speed is lower than automated processes.

- ● Unaffordable for small runs.

- ● Inability to imitate details and master higher quality photograph prints.

- ● Unaffordable for small runs.

Applications

- ● When printing on textiles such as T-shirts, uniforms, and bags.

- ● When printing promotional items that are posters, car decals, and signage.

- ● When printing on glass, ceramics, and industrial panels.

- ● When creating specialty custom packaging and decorative prints.

Gravure Printing: High-Speed Precision for Huge Runs

Gravure is a cylinder-based process. The oh-so-unique “intaglio” printing process is one in which ink is stored in recessed cells engraved in a metal plate, which can be made of copper and chrome, and then transfers ink directly to a substrate on a high-speed web line. Of all the types of printing methods, Gravure delivers benchmark tonal range and predictable color reproduction at scale, especially on films and paper run in a continuous roll. The tradeoff is extremely high initial setup and longer lead times, so it shines only when volumes are genuinely large.

Pros

- ● Outstanding and repeatable clarity in printing, which encompasses the rendering of seamless transitions, rich photographs, solid blocks, and delicate lines while keeping spot mottling to a minimum.

- ● Exceptional efficiency on web presses at operational line speeds that are typical for true mass production.

- ● Low maintenance and high durability of systems as engraved cylinders, can be stored and recycled for many years, with little to no drift in engraving.

- ● Gravure can work with difficult substrates like metallic film, BOPP, and PET, which are often found in high-quality flexible packaging.

- ● Very little to no variation between runs for printing, remarkable for high-stakes composite images that feature large brand colors.

Cons

- ● The most expensive initial setup of all printing techniques due to the extensive time required for cylinder engraving and plating.

- ● Because of the time and cost involved, changeovers become inefficient for small production runs and frequent changes in artwork.

- ● Unless captured and abated, solvent systems pose a greater environmental risk compared to EB or UV chemistry alternatives.

- ● The need for storage and transport of engraved cylinders. For artwork changes, re-engraving cylinders adds time and cost.

Applications

- ● Important for magazines, catalogs, and retail inserts printed in high volumes, where consistency and quality of the photographs are crucial.

- ● Flexible packaging of high quality, snack bags, stand-up pouches, shrink sleeves, gift wrap, and decorative foils on continuous rolls.

- ● Long-life surface finishes, decorative laminates, and wallpaper.

- ● Durable and tamper-resistant imagery for excise products, and security products like stamps and some currency components.

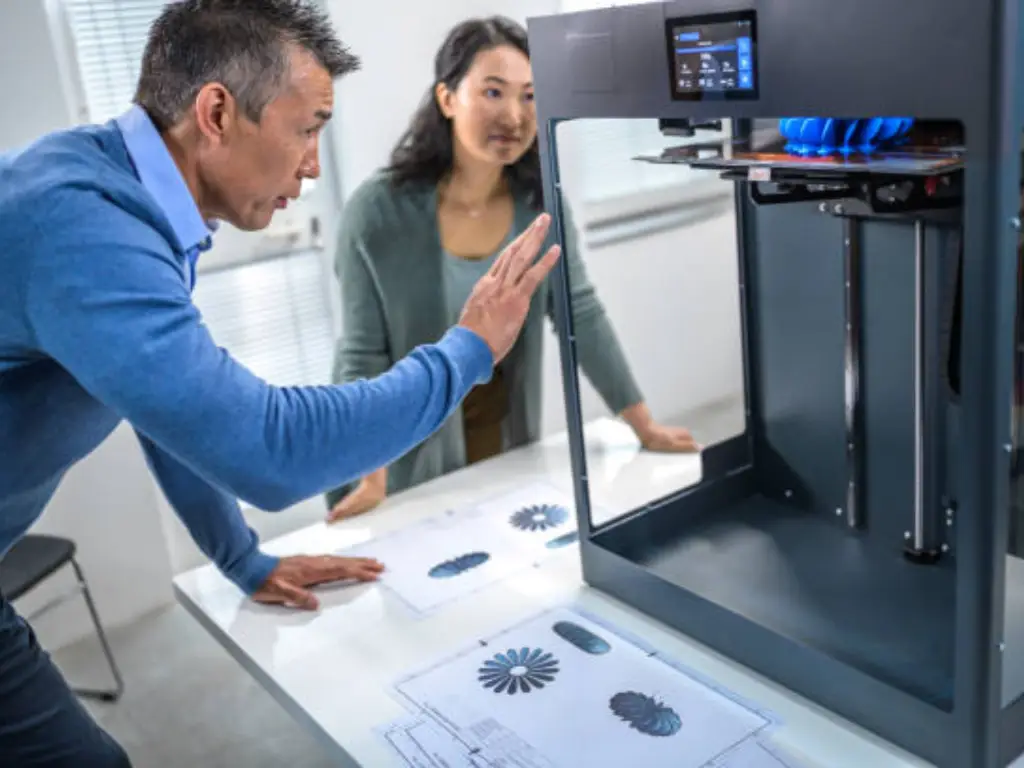

3D Printing: Beyond Traditional Print into Manufacturing

3D printing, or additive manufacturing, is a unique type of printing that differs from all the other printing methods mentioned so far. Rather than printing ink on a surface, a 3D printer melts and fuses materials layer by layer to form a part according to a digital file. Common methods of 3D printing include FDM, SLA, and SLS. It is great for rapid iteration, tooling, and complex geometry above the traditional subtractive and mold-based methods, which are time and cost-inefficient.

Pros

- ● Fast design-to-part cycles for prototypes and small production runs since there is no need for printing plates, screens, or dies.

- ● Produces geometries that cannot be realized or are not economically feasible with conventional printing processes or machining (internal features, lattice structures).

- ● At low volumes, material efficiency and printing cost value are attained; waste is limited to support structures or oversintered material.

- ● Wide range of printing options and adaptable mechanical properties across polymers, resins, elastomers, and metals (DMLS/SLM).

- ● Integration of CAD, slicer, and printer allows for rapid changes and control over different file revisions.

Cons

- ● Volume of production is low compared to other large-scale types of 3D printing, and unit cost improves with scale.

- ● Each method of production has unique limitations, and some, if not much, post-processing will be necessary (sanding, coating, dyeing).

- ● There are limits to how big a part may be produced. Aesthetics and mechanical properties are compromised on the joined sections.

- ● Many processes have some degree of Mechanical anisotropy (layer adhesion), and a specific part orientation may be required.

- ● Compliance with regulations may include additional steps such as testing for food-safe, biocompatible materials.

Applications

- ● Rapid prototypes for consumer goods, enclosures, and custom packaging mockups that speed up sign-off.

- ● Production aids: jigs, fixtures, assembly nests, EOAT, and inspection gauges for effective application on the line.

- ● In the short run, customized end-use parts (dental aligners, prosthetics, bespoke connectors) where personalization is essential.

- ● Functional models for assessing airflow and fluid, examining snap fits, and complex designs that are challenging for subtractive methods.

- ● Educational and R&D settings investigate various processes of printing and manufacturing options before finalizing tooling.

Choosing the Right Printing Method for Your Project

When it comes to the range of printing methods available, carefully considering the needs of your particular project is the first step. To help with your consideration, here are four main things to think about.

- Quantity & Budget:

The amount you plan to print is the biggest determining factor when it comes to cost. For small print runs, typically under 500-1000, digital printing is the way to go simply because you won’t need to pay for printing plates. For larger quantities, the value of offset printing cannot be beaten. It is more cost-effective when looking at the cost per unit. Although it may be the case that for offset printing, the cost of printing plates is reasonable. Finally, Gravure printing is for massive runs, with hundreds of thousands or millions of printed materials.

- Material & Surface:

What are you printing on? If you are working on a project that includes plain paper or cardstock, you have a choice of offset or digital printing. For custom packaging, plastics, or foils, flexographic printing is the industry standard. For textiles, screen printing provides unmatched versatility among the different types of printing methods.

- Required Quality & Durability:

Every advanced technique achieves remarkable quality, though there are subtle differences. For the finest photographic reproductions and intricate details, gravure and offset stand out. Quality for digital prints is more than satisfactory, though it may produce clashing images if the original file is really low-res. When it comes to ultimate durability, particularly for outdoor use, screen printing is king due to its thick ink deposits.

- Turnaround Time:

When it comes to speed, digital printing takes the lead. Because there are no plates to prepare and the setup is minimal, jobs can sometimes be done the same day. In contrast, offset, flexo, and especially gravure printing take significantly longer to prepare for and set up.

| Printing Method | Best For (Quantity) | Quality & Detail | Common Substrates | Key Advantage |

| Offset Printing | High (1,000+) | Excellent | Paper, Cardstock | Low cost at high volume |

| Digital Printing | Low to Medium | Very Good | Paper, Cardstock, Synthetics | Speed & Variable Data |

| Flexography | High (5,000+) | Good | Plastic, Foil, Labels | Speed on packaging |

| Screen Printing | Low to High | Good (Bold Color) | Textiles, Plastic, Glass, Wood | Versatility & Durability |

| Gravure Printing | Very High (500,000+) | Superior | Paper, Film | Unmatched quality at scale |

Why Baishen Pack Is the Right Partner for Your Packaging

When it comes to brands related to food, beverages, coffee, pet food, nutrition supplements, and personal care, the selection of a printing method is merely the start. The actual life that your product gets on the shelf is determined by the packaging that offers protection, convenience, and effective shelf-ability. Baishen Pack is neither a printing firm nor a printing company; we are a manufacturer and international supplier of customized flexible packaging. We offer high-barrier, leak-resistant, puncture-resistant, and high-quality packaging solutions to suit your product by taking advantage of the strengths of digital printing (low MOQ), fast launches, flexographic printing (cost-effective, mid-to-high runs), and gravure printing (very large runs), it offers the highest possible barrier. Whether it is a snack pouch, coffee bag, pet food pouch, nutrition powder sachet, or cosmetic stand-up pouch, our team makes sure that your packaging is not only convenient but also marketable. We also provide environmentally-friendly materials, quick prototyping ,and small-volume trial manufacturing to provide flexibility and influence to your brand.

Ready to discover the perfect packaging solution for your product? Request a free sample or custom quote today and let Baishen Pack help elevate your brand.

Future Trends in Printing Technology

The printing sector is undergoing significant changes, primarily owing to advancements in digital technology, advanced technology, and the need for climate change mitigation. The industry is moving away from its traditional emphasis on mass production and cost-cutting toward more personalized, inter-industry, and eco-friendly solutions. The following are three developments on the horizon in the printing sector that will fundamentally change the industry and that designers, businesses, and creators need to be aware of.

Sustainable and Eco-Friendly Printing

In the business world, green printing is starting to become the gold standard as more and more customers become environmentally conscious and demand green printing. The use of environmentally harmful, solvent-based inks is being substituted with more eco-friendly, water-based, and UV inks. Recycled and biodegradable papers are becoming more common, and the use of energy-efficient printers helps to lower overall waste and the carbon footprint of the printing processes. The use of sustainable, eco-friendly practices in the printing processes is not simply a choice. It is a guiding necessity for the future of the printing business.

Integration of Digital and Traditional Printing

The digitization of business processes and the use of cross-methods in traditional business models are starting to smoothly integrate and form new models. The integration of cross-methods has eliminated the need for businesses to choose the cost-efficient, control-dominant offset and flexo printing methods of traditional printing or the cost-intensive, control-flexible digital printing methods. The new hybrid methods of printing technology allow for high-volume production, while digital methods offer customizable printing. Digitization of the business processes is further enhanced by the use of AI, thus improving the control, precision, and speed of delivery. This delivery speed helps businesses meet the diverse needs of their customers, offering varying degrees of customization and pricing.

Emerging and Cutting-Edge Printing Technologies

In addition to taking sustainability and integration into consideration, new developments are changing what it means to ‘print’. Used in some electronics and medicine, nanoprinting boasts ultra-high resolution. Conductive ink-printing brings together printing and electronics, making it possible to produce flexible circuits, smart labels, and wearables. Laser printing and 3D printing have also advanced significantly and now go beyond prototyping to include full-scale production of items such as medical implants, architectural structures, and other consumer goods. These advanced technologies are no longer limiting printing to flat surfaces. This paints the printing industry a whole new, advanced picture.

Conclusion: Matching the Right Print Method to Your Goals

Each printing technology has its own strengths and is designed for various applications. For instance, offset lithography printing is both economical and capable of great precision for high-volume jobs, while digital presses are flexible and suitable for low-volume, quick jobs. The best choice is the one that best meets the fundamental objectives of the project. Moving beyond just the basic understanding of various printing methods to a more strategic use of printing techniques can be achieved by taking quantity, material, quality, and cost into consideration. This approach to printing will allow the most effective and impactful realization of your idea that will communicate your message in a definite and powerful way.