The modern supply chain is no longer just a vessel; it is a strategic asset in manufacturing packaging across various industries. Glass, metal, and hard plastics have been used by the industry to protect goods with their rigidity for decades. However, today the economic and logistical landscape is different. A mass shift to flexible packaging has been triggered by the advent of e-commerce, the intense level of competition in the retail industry, and the urgency of environmental policies.

This is not just a dictionary of types of flexible packaging. It is an operational analysis of the forms, material sciences, and decision structures needed to navigate through this complex industry. With knowledge of the unique properties and engineering of the film, flexible packaging manufacturers will be in a position to optimize costs, enhance shelf life, and meet regulations.

What is Flexible Packaging? Benefits Beyond the Bag

In its most basic definition, flexible packaging is defined by the fact that non-rigid materials, such as film, foil, and paper, are used to create containers where the shape can be easily changed. Unlike rigid packaging, it is molded to the product it holds, as opposed to a glass jar or a corrugated box.

The economic argument for this change is grounded on the concept of the product-to-package ratio. In hard packaging, the container itself may constitute a significant proportion of the weight shipped, leading to lower costs. Flexible pouch packaging transforms this calculus radically.

Consider the logistics: empty glass jars must be transported by truck fleets to deliver what is essentially air and heavy silica. On the other hand, flexible pouches are shipped flat. A single truckload of empty flexible pouches can in most instances be equivalent to 15 to 20 truckloads of rigid containers. This reduction in weight and volume directly translates to a reduction in fuel consumption and a reduced carbon footprint, which is a significant metric in the present ESG-oriented market.

In addition, the retailing environment has transformed. Brands no longer have to compete to capture the attention of consumers; they have to compete to capture shelf real estate. Flexible packaging, particularly stand-up types, offers a billboard-like surface area that provides the greatest brand exposure with the least amount of space on the shelf.

6 Types of Flexible Packaging Forms (Pouches and Rollstock)

When selecting a packaging solution form factor, it is a trade-off between marketing visibility and filling efficiency. The six dominant market architectures for flexible pouches are as follows:

| Packaging Type | Architecture & Description | Best For (Applications) | The Strategic Advantage |

| Stand-Up Pouch (Doypack) | The Market Standard. Sealed on two sides with a bottom gusset (Round or K-Seal) that expands to support vertical stance. | Snacks, dried fruit, granola, confectionery (50g – 1kg). | Visibility. Replaces rigid boxes with a billboard-like display face; high consumer familiarity. |

| Flat Bottom Pouch (Box Pouch) | The Premium Tier. Features five printable surfaces (front, back, sides, bottom) and a completely flat base. | High-end coffee, premium pet food, artisanal products. | Stability. Unlike Doypacks, it remains stable even with heavy/dense contents; maximizes shelf impact. |

| Side Gusset Bag | The Volume Workhorse. Expands via side gussets; lacks a bottom seal (bottom is formed by product weight). | Bulk coffee beans, rice, flour, cat litter. | Capacity. Maximizes storage volume per square inch of shelf space. Often requires a tin-tie for reclosing. |

| Spouted Pouch | The Bottle Replacer. Integrates a rigid plastic spout/cap into the flexible film structure. | Baby food, beverages, sauces, motor oil, detergents. | Efficiency. Uses up to 80% less plastic than rigid jugs; allows for nearly 100% product evacuation (no waste). |

| Rollstock Film | The Industrial Solution. Continuous laminated film supplied on a roll for automated machinery (VFFS/HFFS). | High-volume snacks (chips), single-serve packets, sachets. | Cost. Lowest cost-per-unit for large runs, but requires significant capital investment in packaging production machinery. |

| Retort Pouch | The “Soft Can.” Engineered to withstand commercial sterilization temperatures (121°C – 135°C). | MREs, wet pet food, shelf-stable soups/curries. | Quality. Thinner profile allows faster heat penetration than metal cans, preserving food texture and taste better. |

Familiarity with Material Structures: The “Sandwich” Logic

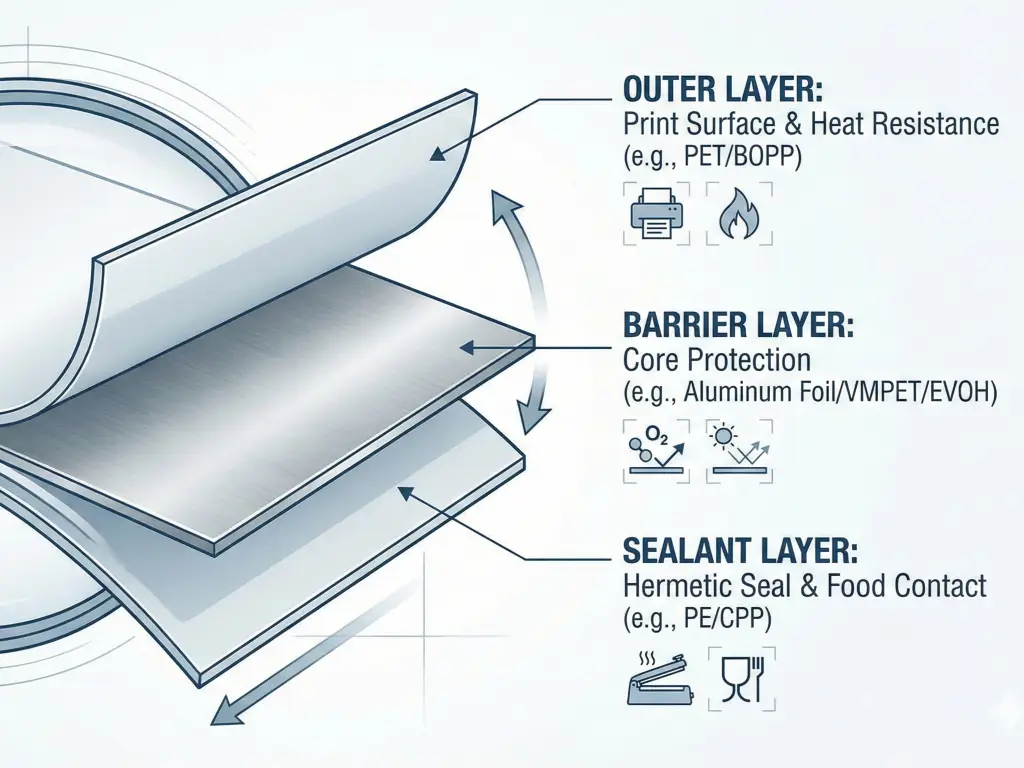

Among the myths is the fact that flexible packaging is nothing more than plastic. In fact, it is a sophisticated composite material. We must think of the film as a sandwich; layers are laminated, and each layer performs a particular engineering task.

The Print Surface (Outer Layer)

The outer layer performs two purposes: it conveys the brand graphics and provides thermal protection so that the film does not melt on the sealing bars during packaging production.

- PET (Polyethylene Terephthalate): The industry standard. It is highly transparent, heat resistant, and tensile.

- BOPP (Biaxially Oriented Polypropylene): This is a cheaper alternative to PET which is normally used on snacks. It is not as heat resistant and is less hard.

- Nylon (BOPA): This is used where puncture resistance is the greatest (e.g., bone-in meat).

- Tactile Finishes: Manufacturers can apply matte finishes or soft-touch finishes to these films to give the consumer a message of high quality at their fingertips.

The Barrier Layer (Core Protection)

This is the most significant level of product preservation, especially in flexible food packaging, including stretch films. It measures the Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR).

- Aluminum Foil (AL): The full barrier. It blocks 100 percent of light, oxygen, and moisture. Products that are highly sensitive like baby formula or medical equipment require this. It, however, renders the packaging opaque and non-microwavable.

- VMPET (Metalized PET): This is a PET film that is coated with a microscopic layer of aluminum. It offers a snack and coffee barrier that is acceptable at a lower price than pure foil, but not as impermeable as AL.

- EVOH / ALOX: The invisible shield. These are evident high barrier finishes. They allow consumers to see the product (beef jerky or cheese) while preventing oxidation.

The Sealant Layer (Inner Contact)

The inner layer must be chemically compatible with the product and must be capable of melting to form a hermetic seal.

- PE (Polyethylene): The traditional sealant. It melts easily and is safe to consume in food.

- CPP (Cast Polypropylene): This is required in high heat processes like retort pouches. PE would melt into a mess during sterilization, whereas CPP would not.

Industry-Specific Applications: Matching Packaging to Product

Different industries have chemical and physical challenges. A generic pouch will fail when it fails to take into account the specifics of the product it holds.

Flexible Food Packaging (Coffee, Snacks, Liquids)

Coffee is a living product; it emits carbon dioxide upon roasting. A common sealed bag would swell and burst. The solution is the combination of a one-way degassing valve, which allows the CO2 to escape and not the oxygen. Oxidation and moisture are the primary foes in the case of liquids and snacks, and OTR and WVTR must be computed correctly to obtain the necessary shelf life, particularly when utilizing a type of flexible packaging.

Pet Food & Treats

Kibble, particularly pet food, is rich in fat. Grease can leak through normal polyethylene with time, leaving the outer part of the bag greasy and the printed inks peeling off. The engineering solution here is a special barrier layer, normally made from high-grade Nylon or special metallization acting as a grease trap. Additionally, bags made with polypropylene fibers should have strong zippers that can hold 10kg or 20kg of the product.

Health, Beauty, and Chemicals

Products that are alcoholic, essential oils, or acidic are considered chemically aggressive. They can hit the adhesives which hold the layers of the laminate together, causing the package to peel off (delamination). These industries should be packaged using high-resistance adhesives and chemically inert inner layers to make sure that the product does not affect the integrity of the package.

The Sustainable Packaging: Trends and Regulations

The industry is undergoing a massive correction process that is being triggered by external regulation and consumer mood. The days of blind dumping are gone.

The Development of Mono-Material (Recyclable PE)

Traditionally, laminates are composite materials (e.g., PET outer + Aluminum middle + PE inner). They are effective but cannot be recycled because the layers cannot be separated. The industry response is Mono-Material structures, which are typically made of PE (Recyclable PE) entirely.

This is a significant technical problem: PE is not highly heat resistant. When trying to seal the inner layer, it is easy to melt the outer layer in the process of making the bag. To address the trade-off between sustainability and manufacturability, some flexible packaging manufacturers like Baishen Package Products have developed special heat-resistant coating and processing techniques that allow these all-PE bags to be used on standard equipment without deformation.

Plastic Taxes (EU/USA) International Laws

Sustainability has turned into a balance sheet item within the flexible packaging market. The UK and the EU charge Plastic Taxes on packaging that does not contain a certain percentage of recycled material or cannot be recycled. The same EPR (Extended Producer Responsibility) laws are being observed in the American markets.

Choosing a cheap, non-recyclable composite material will save a few cents per unit, but will cost dollars in taxes and compliance fees. These regulatory fees must be factored into the Total Cost of Ownership (TCO) of a strategic procurement strategy.

Strategic Selection: 5 Steps to Specify Your Specs

Do not simply “buy a bag.” You must engineer a solution. This five-step audit will assist you in specifying your specifications before you request a quote for flexible pouch packaging.

Step 1: Product Attributes (Physical and Chemical) Analysis

Begin with the product itself. Is it acidic? Is it sharp (dried pasta or walnuts)? The sharp edges require a heavier, puncture-resistant Nylon coating. Highly viscous liquids require a wide spout. In the world of flexible packaging, any variation in this instance leads to failure.

Step 2: Define Filling & Packaging Production Condition

How does the product get into the bag?

- Hot Fill: Standard PE cannot withstand temperatures over 90°C.

- Retort: RCPP is mandatory (Retort CPP).

- VFFS Machines: High-speed automation requires a film with a specified Coefficient of Friction (COF). The machine will jam when the film is either too sticky or too slippery.

Step 3: Decision Lifecycle and Logistics

What is the required shelf life? You cannot afford to compromise on the barrier layer in case you need a shelf life of two years (AL is likely to be needed). Consider the logistics: e-commerce shipping subjects this type of packaging to high-impact drops. Your manufacturer should also perform drop tests to ensure that the burst strength meets courier standards.

Step 4: User Experience Features

The interaction between the consumer and the package stimulates repeat purchases.

- Resealability: In powders (flour/protein), zippers of the regular type often clog. Hook and loop or pocket zippers are needed.

- Dispensing: The package is opened via easy-tear notches (laser scoring) rather than cut diagonally to spill the contents.

Step 5: Finding a Balance between Compliance and Cost

Finally, address the economics.

- MOQ (Minimum Order Quantity): In the case of a new product, you cannot afford to make a commitment of 50,000 units of rotogravure printing. Digital printing has low MOQs (500-1000 units) and no cylinder costs, which are appropriate to pilot the market.

- Compliance: Ensure that the materials are in line with FDA (21 CFR) or EU food contact regulations.

The Unknown Unknowns: Everyday Failures and How to Avoid Them

Even with the correct specs, the manufacturing packaging process can go wrong, especially when part of a package fails. These are the technical pitfalls that make the difference between quality suppliers and the others.

| Failure Mode | The Symptom | The Root Cause (Physics/Chemistry) | The Engineering Solution (Baishen Approach) |

| Seal Failure (Leaking Bottom) | Pouch bursts at the bottom seal immediately after filling, creating a mess on the production line. | Poor “Hot Tack” Strength. The sealant layer has not cooled/crystallized enough to support the product weight instantly after sealing. | Metallocene PE Additives. We formulate sealant layers with Metallocene PE, which provides superior bond strength while the plastic is still hot, ensuring immediate seal integrity. |

| Delamination (Blistering) | The packaging layers peel apart or look like they have air bubbles/blisters trapped inside. | Chemical Attack or Adhesive Failure. Aggressive ingredients (alcohol, essential oils, acids) dissolve standard adhesives, or curing time was insufficient. | High-Resistance Adhesives. We analyze product chemistry first and use 2-component, chemically inert adhesives combined with rigorous 48+ hour curing protocols. |

| Taint & Odor Transfer | The food product tastes “plastic” or has a chemical solvent smell upon opening. | Solvent Retention. Residual solvents from the laminating process are trapped between layers and migrate into the food. | Solvent-Free Lamination. We utilize solvent-free laminating technology to eliminate the risk of odor transfer entirely, ensuring strict food safety compliance. |

Why Co-operate with Baishen Package Products?

The barrier property, compliance tax, and polymer chemistry matrix are difficult to navigate. This is why the choice of flexible packaging manufacturers is as significant as the choice of material.

Baishen Package Products is not a mere printer, but a consultative manufacturing packaging partner. We are founded on the model of the All-In-One solution:

- Consultative Engineering: You are not meant to know the difference between VMPET and AL. Your product needs are audited using the above framework and the optimal structure recommended to use—not over-engineering (wasted cost) or under-engineering (wasted product).

- Hybrid Manufacturing Power: We bridge the startup-enterprise gap. Low-MOQ runs (7-10 day delivery) can be done using state-of-the-art HP Indigo Digital Printing to do market tests. In full-scale production of millions of units, our Rotogravure lines are economical.

- Lab-Verified Quality: Before they reach you, we handle the Unknown Unknowns. We possess a complete set of testing equipment, such as tensile strength, drop testing, and others, so that all flexible pouches meet the ISO, BRC, and SGS standards.

Conclusion

Flexible packaging is a juggling game of form, functionality, and money. It requires a strategic view that considers the entire lifecycle of the product—from the filling machine in the factory to the recycling bin in the house of the consumer.

You might have to switch to rigid containers to save on logistics costs, or you might have to switch to flexible packaging solutions, such as a sustainable mono-material solution, to meet the EU requirements, but the thing is that you must be specific in specification.

Are you ready to develop your packaging strategy?

Do not entrust your material structure to chance. Contact Baishen Package Products today and get a free consultation and material suggestion depending on the product lifecycle.

Are you looking for practical, yet appealing flexible packaging for your product?

Absolutely! When selecting flexible packaging, consider options like stand-up pouches, resealable bags, or custom printed films. These not only protect your product but also enhance shelf appeal. Striking a balance between functionality and aesthetics is key to attracting customers while ensuring your product remains fresh and secure.