In designing a print project, the offset vs digital printing decision is one of the first decisions you will make. Both processes are strong in their way: offset printing is the best process when it comes to large volumes and consistent color, whereas digital printing is faster, more flexible, and variable data capable. Your choice not only impacts the cost, but also print quality, turnaround time, and customization. Regardless of whether you are printing postcards, marketing, or packaging, it is important to know the basic differences between these types of printing. This article dissects the advantages, disadvantages, and the most optimal application of both procedures to guide you to make the best decision of the two techniques based on your particular circumstances in the current dynamic printing marketplace.

What Is Offset Printing?

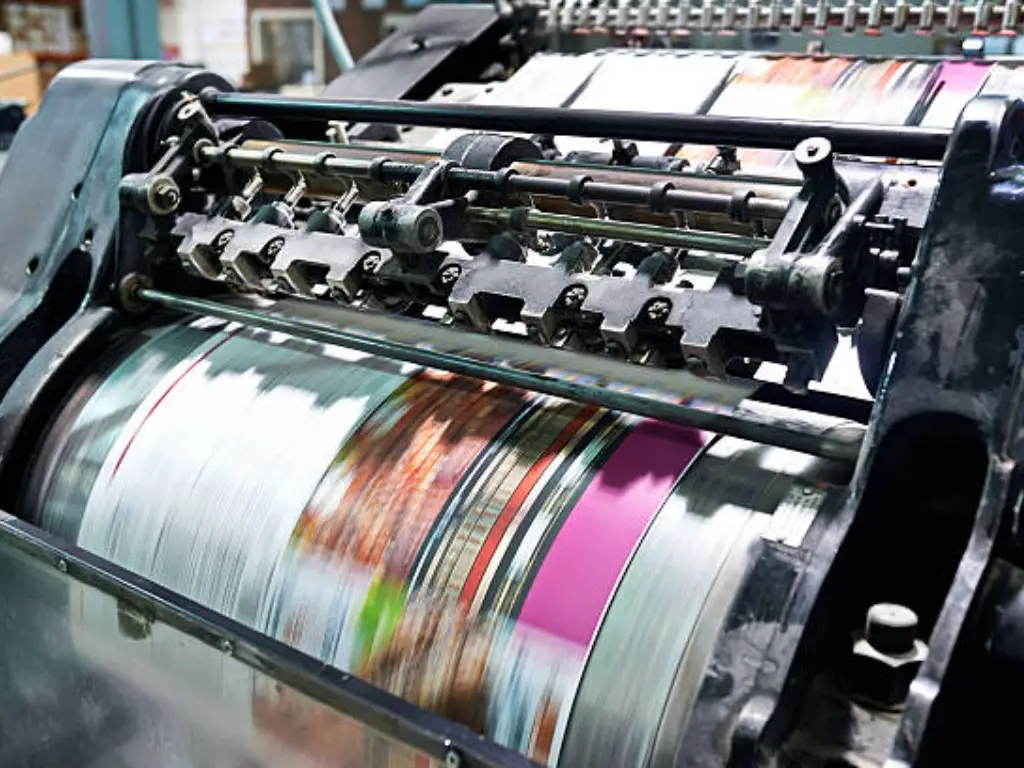

Offset printing is a conventional, mechanical printing process by which ink is transferred to a rubber blanket by an etched metal plate, which in turn transfers the image to the end printing surface, which is usually paper. The name of this indirect method is the origin of the term offset, and it allows for maintaining fine details and consistency during the run. It is normally done with the CMYK model of color, cyan, magenta, yellow, and black, each color on a separate plate.

This method is commonly used in printing companies where there are high-volume applications like newspapers, catalogs, brochures, and packages of goods. The offset presses are most appropriate for the project that deals with large, regular batches of the same print. Although they are expensive to set up, the printing industry depends on offset to provide a print quality, reliability, and the capability of keeping close control of color on thousands of copies.

Pros of Offset Printing

- ● Excellent color accuracy and consistency, especially with PMS spot colors

- ● Economical for large quantities—the more you print, the lower the unit cost

- ● Wide compatibility with traditional offset stocks and specialty papers

- ● Produces sharp, high-resolution detail and smooth gradients

- ● Compatible with special finishes like metallic inks, varnishes, and coatings

- ● Long-proven and scalable method in the printing industry

Cons of Offset Printing

- ● Requires a complex setup involving plates and calibration

- ● Not suited for short runs or projects that change frequently

- ● No support for variable data or one-to-one customization

- ● Longer turnaround time due to plate preparation and drying

- ● Generates setup waste and uses more harmful chemicals

- ● Less flexible when printing different versions in a single job

What Is Digital Printing?

Digital printing is a more modern, computer-based method of printing, involves sending an electronic copy of the data to a digital printer, which prints the image onto the material using toner or liquid ink and does not require metal plates. This is instant and non-messy, so it is very useful when it comes to quick tasks and small runs that demand customisation or regular revision.

Inkjet and HP Indigo presses are modern digital printers that can print on a broad range of paper stocks and even flexible packaging films. Digital printing is the solution of choice when the data to be printed is variable, that is, when the data is different on each piece, as in names, barcodes, or QR codes. It is employed in the business card industry, marketing postcard industry, direct mail industry, and packaging prototype industry, among others.

Pros of Digital Printing

- ● No setup plates—faster production and easy file-based printing

- ● Ideal for short runs, samples, and time-sensitive projects

- ● Enables full personalization through variable data printing

- ● Minimal setup waste—uses exact amounts of ink or toner

- ● Works with various paper types and synthetic packaging materials

- ● Faster turnaround time, suitable for just-in-time print jobs

Cons of Digital Printing

- ● May lack the color precision of offset, especially for brand-specific tones

- ● Less cost-effective for high quantities due to fixed per-unit costs

- ● Limited options for specialty inks, coatings, and finishes

- ● Risk of banding or inconsistency in large solid color areas

- ● May not handle all traditional offset stocks equally well

- ● Fewer options for custom finishing on some digital machines

Key Differences Between Digital Printing and Offset

In offset against digital printing, there is no standard formula. The best print process is based on the job quantity, color requirement, customization requirements, and the time frame. We have presented the key differences between the two in terms of important technical and strategic dimensions below.

| Feature | Offset Printing | Digital Printing |

| Setup Time | High (requires metal plates and calibration) | Low (prints directly from electronic files) |

| Best For | Large quantities (e.g., 3,000+ copies) | Short runs or one-off prints |

| Unit Cost | Decreases with volume | Stable regardless of volume |

| Color Accuracy | Excellent, supports PMS spot colors | Very good, but less precise for exact brand colors |

| Print Quality | Superior, ideal for high-detail, consistent output | High quality, improving rapidly with new technology |

| Personalization | Not suitable for variable content | Perfect for variable data printing |

| Material Flexibility | Best with standard paper types | Compatible with diverse materials and packaging films |

| Turnaround Time | Longer setup, but fast for high-volume jobs | Quick production, ideal for tight deadlines |

| Common Uses | Magazines, packaging, books, high-volume brochures | Direct mail, labels, custom marketing materials |

Cost Structure (Upfront Costs vs. Per Unit Price)

One of the most obvious contrasts in the offset vs digital printing debate is the cost model. In offset printing, a fixed setup must be used, which includes metal plates, ink adjusting, and adjusting the machine. Such initial investments render it unsuitable for short runs. But the price per unit falls dramatically with volume, especially when one is above 3,000 or 5,000 of the same item.

In comparison, digital printing does not require plates and setup. This causes it to be much more cost-effective on short runs (less than 1,000 units), versioned materials, or on frequently changing designs. The price is comparatively fixed on the page, but it is more flexible in terms of working with variable data, and thus it is more appropriate to use it in personalized content or small-scale projects.

Practically speaking, publishing houses, marketing departments, and retail brands frequently institute offset when the materials are being printed in large, consistent quantities, and they use digital when the runs are limited, when the campaigns are conducted in a segmented fashion, or when the printing process is just-in-time.

Print Quality and Color Control

Offset printing has dominated color accuracy as well as detail sharpness, especially in premium product segments like luxury goods packaging, art prints, or critical brand marketing. It supports PMS spot colors, smooth color gradients, and precise ink coverage using wet ink that interacts naturally with the paper surface. This enhances the final printed output visual, especially over a large, consistent area.

Digital printing, which was once regarded as inferior, has evolved tremendously. Today’s digital presses, powered by HP Indigo or high-end inkjet, are capable of 2400 dpi resolution. Color matching, however, remains more variable when solid spot colors or large areas of uniform tone are printed.

For brands requiring absolute consistency across thousands of units or print facilities, offset remains the preferred method. For general commercial needs, digital print quality is often indistinguishable to the average viewer and more than sufficient for most business materials.

Variable Data and Customization Capabilities

Variable data tasks are best suited to digital printing. It can change text, images, barcodes, or layouts sequentially using dynamic electronic files, without halting operations. This is crucial for direct mail, personalized offers, serialized packaging, and advanced ticketing.

In offset printing, modifications cannot be made mid-run. Each version would necessitate a new plate, complete recalibration, and significant time and expense, rendering variable data impractical. Even small amendments incur downtime resetting the entire printing workflow, severely compromising throughput efficiency.

For market-segmented real-time personalization—typical in retail and e-commerce—offset cannot compete with digital’s targeted agility. It is not about flexibility; rather, strategic responsive print strategies are enabled through digital capabilities.

Print Speed and Turnaround Times

Size and complexity define print speed. Digital systems need no prep work, and printing starts immediately as soon as files are queued, making same-day orders feasible. Instantly required materials, such as those needed during trade shows or agile marketing campaigns, are easily accommodated.

In contrast, offset printing has slower lead times because of the need for plate setup, proofing, and press alterations. However, after everything is properly configured, this method can produce tens of thousands of copies per hour with incredible consistency. For extended, repetitive runs like high-volume books, catalogs, or newspapers, offset printing still outshines digital in sustained throughput.

In the end, if quick turnarounds on changeable, low-volume work is required, then digital remains the better option. If scaling by volume and long-term scheduling takes priority, offset maintains its position as the production workhorse.

Material Compatibility (Paper vs. Flexible Packaging Films)

Offset presses are tuned to work with more traditional substrates, such as coated and uncoated papers, newsprint, and board stocks. They are most suitable for materials with uniform attributes, thus fit in brochures, corporate stationery, and publications that have high volumes.

Digital presses are more versatile. Most of the modern models have the capability of printing on synthetic papers, polypropylene films, adhesive labels, and even flexible packaging employed in the food and health industries. Digital has a specialty advantage because it can adjust to various materials, thicknesses, and finishes quickly.

In addition, digital printing enables short-run testing of unusual stocks- helpful in R&D, seasonal campaigns, or small-volume product runs. Whereas offset is still the most popular in printing in the traditional paper format, digital has widened the horizon of what can be printed in various forms of materials.

Environmental Impact: Which Printing Method Is Greener?

In assessing the environmental impact of offset vs digital printing, it is obvious that each of the two has its trade-offs. In offset printing, a more complicated assembly is used, and wet inks, which potentially contain volatile organic compounds (VOCs), metal plates, and cleaning solvents are used. Not only do these materials need special care when being handled and discarded, but they also increase the amount of waste generated, particularly in the short-run situation. Since the offset presses are tuned to high-volume printing, the overprinting is typical to achieve the cost efficiency, which results in the waste of unnecessary paper and more energy consumption.

Digital printing, on the other hand, does away with many of these processes. It does not use any plates or chemical washes, but prints directly off of the electronic files, making it use fewer materials and produce fewer emissions. Small amounts of ink or toner are used, making it easy to reduce wastage. Digital is also able to support short-run, localized production, which means companies can print nearer to their end users, which limits the carbon footprint caused by transportation. Although digital presses do use energy, especially when it comes to color-intensive work, the general impact is usually smaller in small to medium volumes.

That being said, both approaches are not sustainable in themselves unless material decisions are made. Paper sourcing, the formulation of ink, energy usage, and recycling also inform the environmental impact of any print job. The two technologies, offset and digital, are also still relatively developing in this area, and numerous printing agencies are today providing certified sustainable alternatives on both systems.

Offset Printing vs Digital Printing: Final Thoughts

Whether to use offset or digital printing will eventually depend on the size and priorities of your project. When your emphasis is on high volume printing, color quality, and cost-effective printing over a long period of time, offset printing is still the superior option, particularly when you need to print books, magazines, packaging, and large-scale marketing materials where consistency is the key.

By contrast, when speed, flexibility, or personalization is your primary goal, there are obvious advantages to digital printing. It is suitable to use short runs, quick prototyping, or projects that contain variable data, require being updated regularly, or meet a deadline. It allows the marketers and designers to make iterations fast, test various layouts, and save on waste by printing only the required pieces.

The two techniques are useful in the contemporary printing environment. Instead of perceiving it as the offset vs digital printing competition, it would be better to consider it as complementary technologies. Having a knowledge of their distinction helps you to choose the appropriate method for the appropriate job, and hence, there would be improved outcomes, improved efficiency, and improved returns on investment.

Baishen Pack: Best Printing Method for Flexible Packaging

The selection of the printing method in the flexible packaging industry is not a mere technical decision but directly influences the protection of the product, its look on the shelf, and the conveying of the brand message. We have the expertise in structural packaging and the experience of the latest printing technologies in order to provide our customers not only with a bag but with a ready solution to the market.

Regardless of whether you have one product or hundreds of SKUs, we apply the right printing solution to your strategy. In the case of test markets, small runs, or fast launches, our digital press can support ultra-low MOQs down to only 500, in full color, high resolution. To run large volume jobs, our gravure and flexo printing abilities allow high cost-effectiveness and color accuracy at scale.

In addition to printing, we have in-house production, certified food-grade material, and custom features, including resealable zippers and metallic finishes. Our team knows the requirements of the food, pet, supplement, and beauty industries, and we design packaging that performs throughout the entire product life cycle.

Looking to have flexible packaging that accompanies you in all your stages of growth? Baishen Pack- partner with us where performance, quality, and flexibility are.