Introduction

The packaging arena is changing rapidly, and flexible packaging materials are at the very core of the change. The packaging market, as it stands today, has challenged both the manufacturers and the brands to think differently due to the demands of their consumers. Whether in the food industry or the pharmaceutical industry, flexible packaging is fast turning out to be the preferred solution to companies that are keen on both protecting their products and being environmentally conscious.

What is the reason behind the change? It is not only aesthetics. It is about shelf life, cost saving, and food waste reduction. The flexible packaging industry is on an upward trend, and, as such, it is essential in enabling a circular economy, all the while maintaining a balance between functionality and environmental responsibility. A basic idea of how flexible packaging materials perform and why they are important puts businesses in an actual advantageous position in terms of competing with others in the international markets.

In this guide, we will investigate the design of flexible packages, their main advantages, and future trends that will form the next decade. This is your guide, whether you are new to the packaging world or want to perfect your strategies.

Understanding Flexible Packaging: Beyond the Basics

Flexible packaging does not consist only of plastic bags or basic wrappers. It means the packaging material, such as plastic films, paper, foil, and laminate, can be readily adapted to various product shapes and needs. Such flexibility enables brands to create functional, appealing, and packaging that meets the needs of modern consumers.

Excellent barrier is one of the greatest flexible packaging benefits. Moisture, oxygen, and light-sensitive products can be safeguarded to prolong shelf life and preserve product quality. Food, pharmaceuticals, and personal care industries are some of the industries that depend on this protection to maintain fresh and safe products.

It is not only the safety of the products that makes flexible packaging gain more and more popularity, but the convenience as well. Such things as resealable openings, spouts, or easy-tear designs enhance consumer usage daily. And since these packages are light, they will facilitate cutting down the shipping expenses and general environmental degradation.

Flexible packaging materials are a convenient, eco-friendly alternative as companies abandon the practice of rigid packaging. These offer a combination of protection, efficiency, and user experience and are set to become a key component in the packaging market in the present day.

Key Flexible Packaging Materials Explored

The selection of materials is one of the key factors that define the effectiveness of flexible packaging. Both materials offer unique functional benefits, barrier properties to sustainability, and are chosen depending upon the individual product and market requirements. The following is a description of the major flexible packaging materials currently in use.

Plastic Films: The Structural Foundation

Most flexible packaging formats are centered around plastic films, which offer mechanical strength, barrier protection, and versatility. The most popular ones include:

- ● Polyethylene (PE): PE is flexible, sealable, and strong, and comes in the following forms: LDPE, HDPE, and LLDPE. LDPE is popular in bread bags and produce films, whereas HDPE is utilized in stiffer pouches. LLDPE is preferred in stretch films and in uses where puncture resistance is needed.

- ● Polypropylene (PP): PP is highly moisture resistant and is also very clear; it is available in BOPP and CPP forms. BOPP is crisp and printable, which is why it fits well in snacks and confectionery, whereas CPP can be used in higher heat applications such as retort pouches.

- ● Polyethylene Terephthalate (PET): PET offers good strength and thermal stability. It is regularly utilized as the printable outer ply in laminated package structures, mainly where high durability and graphics are required.

- ● Polyvinyl Chloride (PVC): PVC is being slowly replaced in most markets by environmental concerns, but is still used in certain applications where its cling and clarity properties are needed, like wraps on fresh produce.

- ● EVOH (Ethylene Vinyl Alcohol): EVOH is frequently used as a thin barrier layer in multilayer packages. Its outstanding oxygen resistance greatly increases the shelf life of oxygen-sensitive foods, including meats and dairy.

Foil: Maximum Barrier Protection

Aluminum foil is an essential element of flexible packaging when it comes to the products that require the ultimate protection. Foil layers are typically applied in packaging coffee, pharmaceuticals, and shelf-stable prepared foods, with nearly total resistance to moisture, oxygen, light, and aroma. It is also thermally conductive and therefore applicable in heat-sealable structures.

Paper: Functional and Renewable

Flexible packaging is also incorporating paper materials, whose renewable character and printability are considered an asset. Paper can form part of functional barrier layers as well as sustainable brand positioning when used in combination with plastic or foil layers. Common forms are:

- ● Kraft Paper: It is a strong and natural-looking paper commonly used with dry products.

- ● Coated Paper: Greater moisture or grease resistance, popular in snack packaging.

- ● Greaseproof Paper: This is particularly used with oily or baked food.

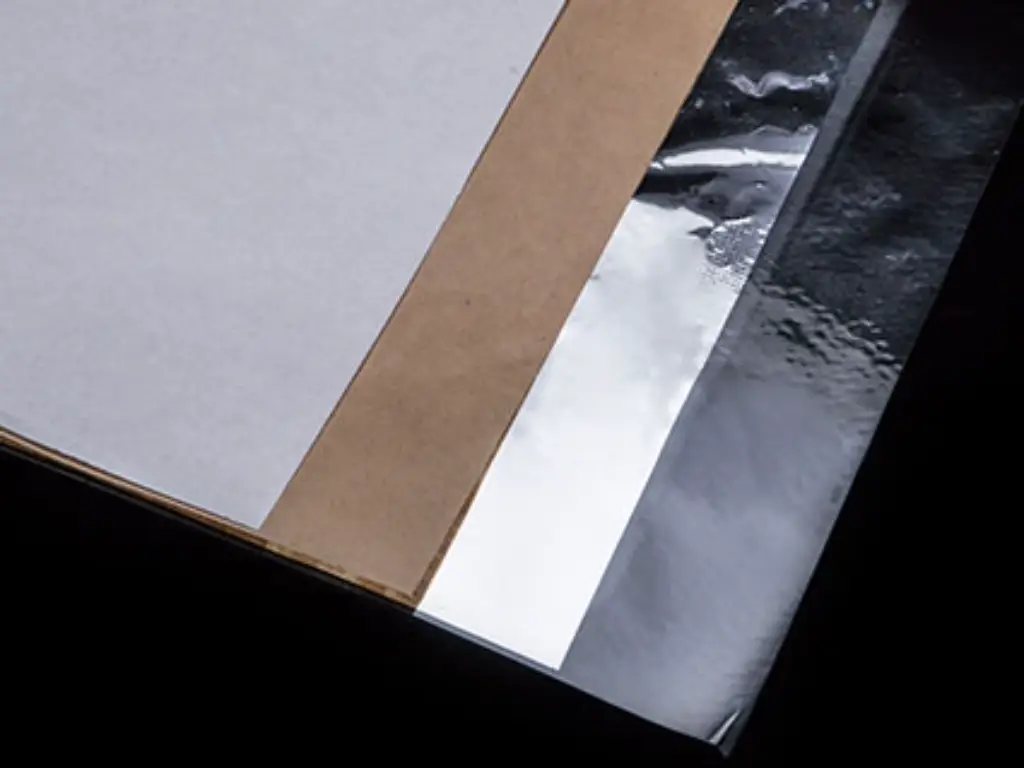

Laminates & Multilayer Structures

The modern flexible packaging design revolves around laminated and multilayer structures. Manufacturers can optimize barrier properties, mechanical strength, and print surfaces to suit particular product requirements by laminating layers of plastic, foil, and paper. Common forms may be:

- ● PET for durability and printability

- ● Aluminum foil for maximum barrier protection

- ● PE or PP for sealability

This layering approach makes high-performance packaging flexible enough without affecting production efficiency.

Bio-based & Compostable Materials

Bio-based and compostable films are positioned as alternatives to conventional plastics, driven by the sustainability agenda. Polylactic Acid (PLA) and cellulose-based films are renewable solutions to materials, especially in fresh produce and dry snacks. These materials, though still developing in recyclability and price competitiveness, demonstrate the industry’s dedication to decreasing the environmental impact.

Sustainability in Flexible Packaging: Innovations and Impact

With the growth of sustainability as a vital concern in all industries, flexible packaging is also developing in such a way that it responds to the issues of environmental degradation, without affecting the integrity and performance of the product. The essential fields are the following, which are the main areas of development towards a sustainable advance in this area:

- ● 1. Advancements in Mono-Material Structures

The shift towards mono-material packaging can be regarded as one of the most important inventions. Flexible packaging would be much more recyclable by making them mostly from one plastic resin, either polyethylene (PE) or polypropylene (PP). This minimizes material incompatibility within recycling streams, which is aligned with the models of a circular economy and enhances the overall recyclability of flexible packaging solutions.

- ● 2. Development of Biodegradable and Compostable Materials

Flexible packaging manufacturers are keen on investigating biodegradable and compostable flexible packaging. These materials are supposed to decompose after exposure to certain environmental conditions, and this is an effort to minimize the landfill waste. Although the existing applications are still confined to specific types of products or geographical areas, they mark a major milestone on the road to packaging innovation and its alignment with the worldwide sustainability agenda.

- ● 3. Reducing Energy Consumption in Production

Another important area is the optimization of energy used in flexible packaging manufacturing. The contemporary processing technology of films and laminates is designed to reduce the energy intensity without performance or barrier property compromise. Not only does this reduce environmental impact, but it also falls in line with greater industry trends of carbon reduction.

- ● 4. Lightweight Design for Resource Efficiency

The design of lightweight packaging helps in creating sustainability because it reduces the use of material in the package without affecting its usability. Material weight reduction will reduce transportation emissions and the total environmental impact. Meanwhile, it is a more cost-efficient method, which offers environmental and economic value to brands and manufacturers.

- ● 5. Building Recycling Infrastructure and Closed-Loop Systems

Sustainability is also being pursued in areas beyond the package design to include end-of-life solutions. The flexible packaging sector is working more closely with recycling schemes to develop more efficient collection and processing infrastructure. When companies engage in closed-loop recycling programs, they can minimize waste, and they also enhance their obligation to proper resource management.

Applications & Benefits Across Diverse Industries

The uses of flexible packaging materials have been imperative in industries because of their flexibility, efficiency, and functional capabilities of satisfying both functional and branding requirements. Whether the application is in food or pharmaceuticals, these solutions keep on getting advanced to meet the demands of modern consumers and the requirements of the sector.

| Industry | Applications | Key Benefits |

| Food | Resealable pouches, sachets, rollstock for snacks, condiments, frozen foods | Maintains freshness, extends shelf life, and reduces food waste |

| Pharmaceuticals | Sachets, blister packs, laminated films for tablets, powders, and liquids | Protects products from contaminants, ensures regulatory compliance |

| Personal Care | Flexible tubes, pouches with spouts or resealable features for lotions, shampoos | Enhances convenience, supports creative branding, and improves user experience |

| Pet Food | Resealable bags, portioned packs | Retains freshness, improves storage convenience, offers recyclable options, and grows |

| Cross-Industry | Packaging for various consumer goods | Lightweight structure, cost-efficient logistics, and sustainability integration |

Flexible Packaging: From Raw Material to Finished Product

Flexible packaging manufacturing is a highly organized process, which involves converting raw materials into functional high performance packaging solutions. All the stages are well planned to achieve material efficiency, product protection, and brand presentation.

- ● 1. Substrate Selection

It starts with choosing an appropriate base material, i.e., PE, PP, PET, aluminum foil, or paper, depending on the property needed, e.g., flexibility, barrier, or printability. The material selection is very crucial so that the packaging serves its purpose of functionality and aesthetics.

- ● 2. Printing

Designs, branding, and product information are applied using advanced printing technologies such as flexographic, rotogravure, and increasingly digital printing. Accurate, quality printing helps generate shelf appeal, along with alleged consumer recognition.

- ● 3. Coating

Functional coatings are used to enhance certain material characteristics, e.g., to make them moisture-proof, abrasion-resistant, or sealable. These coatings are important in terms of maximizing the performance of the packaging.

- ● 4. Lamination

Layers of materials are laminated to form composite structures to provide improved protective and mechanical performance. Here is where other factors can be added, such as aluminum foil to provide excellent barrier protection.

- ● 5. Conversion and Forming

Conversion of the laminated material into a desired packaging format (pouches, sachets, or wraps) is then done by operations such as cutting, folding, and heat sealing. Special touches such as resealable zippers or spouts may be added at this point.

- ● 6. Quality Control and Finalization

Final packaging undergoes stringent quality control measures to make sure it satisfies industry requirements regarding strength, integrity of the seal, and appearance before shipping.

In the process, manufacturers are also gradually maximizing on recyclable materials, less energy use, and optimum designs that use less material. The practices contribute to the broader sustainability ambitions and the circular economy.

Navigating Market Trends & Future Outlook

Flexible packaging is a sector that is changing tremendously, thanks to technology and the changing needs of the market. These trends are critical to be understood by the stakeholders who want to remain competitive in a fast-paced global world.

Sustainability is one of the key emphases. With regulatory systems becoming stricter and consumers increasingly aware of environmental problems, the industry is moving faster towards recyclable, mono-material packaging. Simplifying material structures would allow manufacturers to enhance recyclability, contribute to the efforts of the circular economy, and lower environmental harm.

Another important development is digital printing. Digital printing is gaining popularity in markets (personal care, cosmetics, and food, etc.), as it provides flexibility, shorter lead times, and the opportunity to customize the packaging design. This technology also enables the brands to act more effectively in response to consumer preferences and market trends.

Sustainability has become cost-efficient. Flexible packaging is lightweight, which decreases the transportation cost and minimizes the material usage. With the worldwide markets focusing on environment-friendly solutions, biodegradable films and compostable materials are gaining popularity.

In the future, advancement will be spurred by material innovation. The industry issue is to strike a balance between performance, e.g., barrier properties, product protection, and environmental responsibility. The future of flexible packaging will still be determined by further developments in multilayer constructions, bio-based materials, and recycling.

How to Choose the Right Flexible Packaging Material?

Choice of flexible packaging materials is a tactical move that determines product safety, brand image, and sustainability record. An explicit model assists brands in making informed decisions that are consistent with functional and environmental priorities.

- ● 1. Product Requirements

To select it, one starts by examining the individual protection requirements of the product. Moisture, oxygen, or light-sensitive products, such as snacks, pharmaceuticals, or coffee, may need sophisticated barrier layers, such as aluminum foil or high-precision polymer coatings. Less-sensitive items can get by with simpler constructions made of recyclable plastics like polyethylene (PE) or polypropylene (PP).

- ● 2. Sustainability Considerations

The role of sustainability goals becomes more and more decisive. Environmentally-conscious companies might be more interested in mono-material solutions to facilitate recycling or the use of renewable resources like paper laminates on dry goods. Material selection according to the principles of the circular economy can satisfy not only regulatory requirements and consumer demands about environmentally friendly packaging.

- ● 3. Functional Features

The user experience can be enhanced greatly with functional features such as resealable zippers, spouts, or easy-open features. Such attributes are particularly important in markets such as personal care, pet food, and household goods, where the ease of use translates into consumer happiness.

- ● 4. Cost-Benefit Balance

Cost is still a consideration; however, it should be weighed against durability, beauty, and the environmental impact of the material throughout its lifecycle. The aim is to go beyond lowering upfront expenses and maximize long-term value to the brand and the consumer.

This systematic process enables companies to make balanced decisions that are future-focused, and material selection serves product integrity and positioning.

Baishen Pack: Your Trusted Partner in Premium Flexible Packaging

Since 2012, Baishen Pack has empowered global brands with high-quality custom flexible packaging. We specialize in food-grade, FDA/SGS/ISO certified materials, ensuring product safety and compliance. Leveraging advanced HP Indigo digital printing, we achieve up to 97% PANTONE® color matching for stunning shelf appeal. Our industry-leading turnaround delivers digital print orders in just 7-10 business days – significantly faster than competitors. With flexible MOQs starting at 500 units, we support all scales. Our rigorous in-house QC, including comprehensive barrier and durability tests, guarantees superior moisture, oxygen, and puncture resistance. Choose Baishen Pack for ultimate product protection, extended shelf life, and a decisive market advantage.

Overcoming Challenges & Maximizing Opportunities

The flexible packaging materials have a great advantage, yet they possess certain difficulties. By responding to these challenges through specific strategies, the risks can be reduced, and it will create the gateway to innovation and a competitive edge.

- ● Recyclability Challenges and Solutions

Recyclability of multi-material structures, in particular those including aluminum foil or polymer mixtures, is one of the major challenges in flexible packaging. Nevertheless, the development of mono-material solutions, including polyethylene (PE)-based laminates, is enhancing compatibility with recycling systems. The work in the industry to establish uniform recycling guidelines also speaks in favor of flexible packaging inclusion in the circular economy.

- ● Regulatory Compliance

Industries such as food, pharmaceuticals, and personal care have high regulatory requirements of hygiene, safety, and product integrity. New barrier coating innovations, hygienic lidding, and tamper-evident designs make certain that flexible packaging will reliably continue to fulfill these requirements and that it will do so efficiently during production.

- ● Sustainability Expectations

As consumers become more environmentally conscious and global regulations become stricter, brands face the rising pressure to implement sustainable packaging solutions. This obstacle is also an important opportunity: by actively switching to recyclable, compostable, or renewable material alternatives, companies can reinforce brand image and establish a generation of consumers.

- ● Technological Advancements and Efficiency Gains

Advances in technology are spurring the enhancement of the entire process of producing flexible packaging. Superior printing methods, automation, and energy-efficient manufacturing reduce the cost of production without compromising on quality. Companies that embrace the power of such technologies will have a competitive advantage in operations and will be in a better position to deal with the changing market expectations.

Through adequate maneuvering of these issues, companies may turn the possible impediments into growth drivers and establish themselves as pace setters in innovation and sustainability in the flexible packaging sector.

Conclusion

The use of flexible packaging material has emerged as a pillar in contemporary packaging solutions in any industry. Their sustainability, product protection, and shelf life are the factors that give them the advantage in the current competitive environment. Whether that is protecting pharmaceuticals against contamination, preserving the freshness of snacks, or providing a sustainable alternative to rigid materials, flexible packaging is defining the future of packaging and consumption of goods.

The flexible packaging business will keep advancing, and companies that keep abreast of trends, such as recyclability, digital customization, and sustainable materials, will keep ahead of the game. The vital importance of flexible packaging solutions in enabling a circular economy can hardly be overestimated, as environmental awareness further drives consumer expectations as well as regulatory frameworks.

Selecting a proper packaging material is not a mere technical decision; it is a strategic decision that can affect the entire process of shipping, customer satisfaction, and much more. When approached correctly, flexible packaging is not a container at all, but rather a silent ambassador of a brand, taking its products safely, efficiently, and sustainably into the future.