In flexible packaging, the quality of the seal directly impacts the integrity of the product. Creating the longitudinal seal on a package formed from roll stock is a vital choice in packaging design and operations. This decision influences material costs, production efficiency, product safety, and shelf life. In the vertical form fill seal (VFFS) and horizontal form fill seal (HFFS) applications, the two main heat-sealing methods are fin seals and lap seals.

Although both seals accomplish the function of “continuously and durably” merging two edges of a material, the mechanisms for accomplishing this purpose, as well as the operational advantages, differ. Thus, the need for and understanding of these differences in the packaging world is vital not just for the sake of knowledge, but for unlocking the potential of the packaging lines in meeting the commercial and regulatory requirements of the product.

This guide provides an objective comparison of the fin seal and lap seal, including construction, performance, material compatibility, and best use scenarios. It outlines decision-making and provides a troubleshooting guide for common sealing problems, thus empowering packaging professionals to align a decision with product and production goals.

What Are Fin Seal and Lap Seal?

The main difference between a fin seal and a lap seal is in the manner in which the edges of the film are attached during the heat-sealing process. This structural difference determines the kind of packaging material that may be utilized and the amount of seal integrity that may be attained.

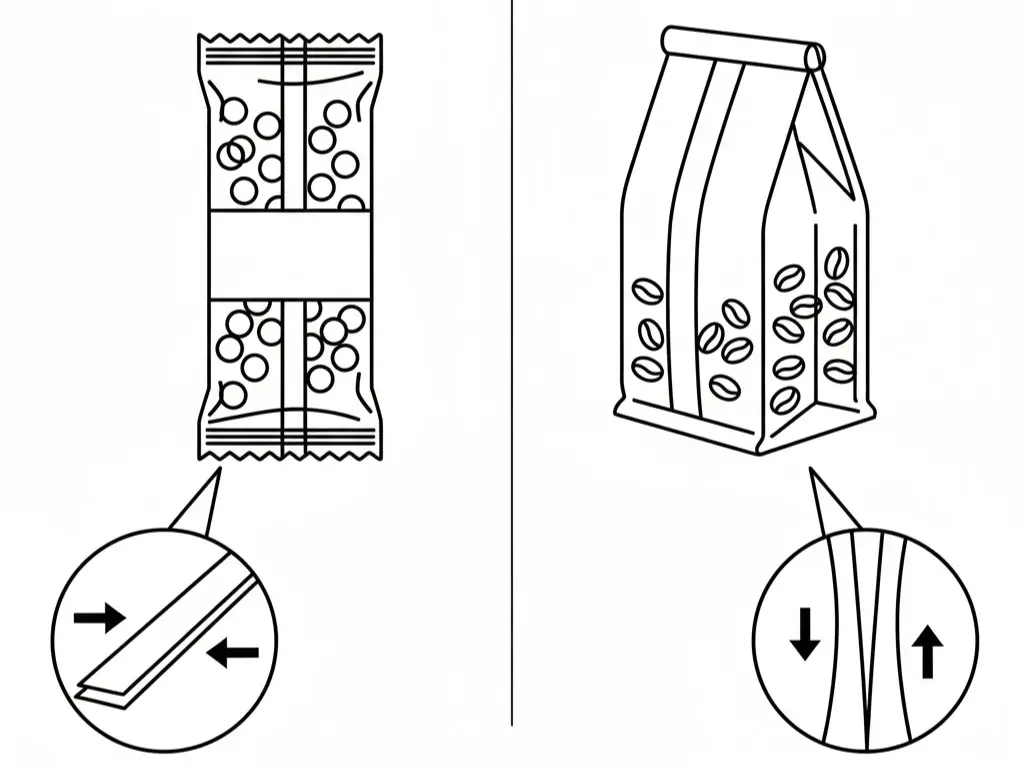

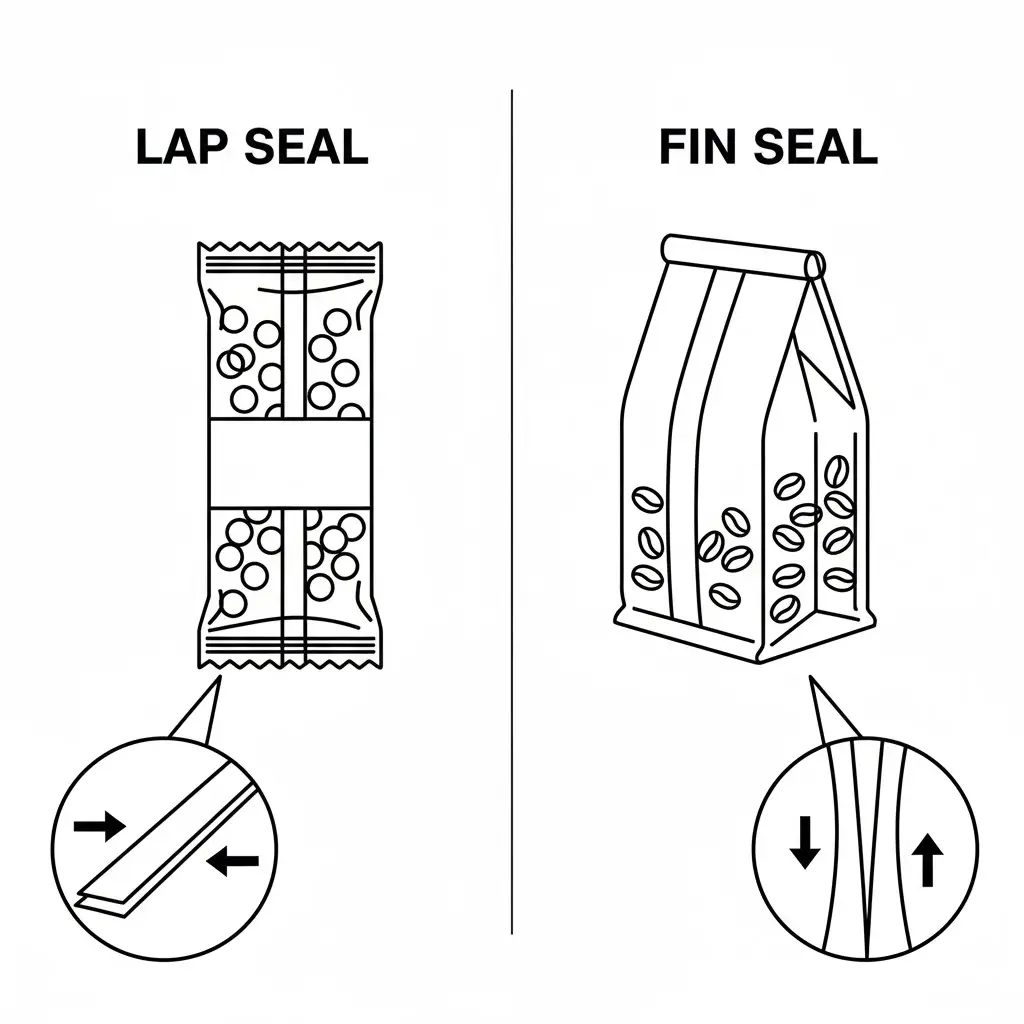

A Fin Seal involves the uniting of the two interior surfaces of a film packaging with heat and pressure. The seam, or rather the fin that ensues, sticks out of the body of the package much like a little fin. This seal is created by folding up the film, ensuring that the sealant side on the inside of the film is sealed to itself (inside-to-inside). This is a basic method to attain a strong bond in the case of multi-layer or laminated films, the outer layer of which is not heat-sealable. The final seal is usually folded a flat way, covering the package to present it better.

A Lap Seal, on the other hand, is that which is made by overlapping the two edges of the film and sealing the inside surface of one edge to the outside surface of the other (inside-to-outside). The technique is done to produce a smooth surface without a fin sticking out. To work successfully, a lap seal, both the inner and outer surfaces of the film in the area of a seal, should be compatible and can create a long-lasting seal under the influence of pressure and heat exerted by the bars of the seal. This necessarily restricts the kind of material that can be used in this sealing technique. The main benefit of a lap seal is that it uses less material compared to a fin seal since it takes a smaller width of the film than a fin seal to cover the same size package.

Fin Seal vs Lap Seal: Key Differences at a Glance

To assess the two sealing options, it is imperative to break down and technically understand the mechanical formation of each seal. The two major components that differentiate a fin seal from a lap seal are the sealing and alignment of the edges of the film in the heat-sealing process. These two components determine the type of packaging material that can be used and the seal integrity that can be attained.

| Feature | Fin Seal | Lap Seal |

| Seal Strength | High. Sealing two identical inner sealant layers creates a very strong, reliable, and hermetic bond. | Variable. Seal strength depends on the compatibility of the inner and outer film layers. Generally considered to have a lower seal strength than a fin seal. |

| Material Usage | Higher. The formation of the “fin” requires an additional 1/2 to 3/4 inch (12-20mm) of film width per package. | Lower. The minimal overlap allows for a significant reduction in material width, typically saving 10-15% of film, leading to less cost. |

| Film Compatibility | Excellent. Compatible with nearly all flexible films, especially complex flexible film laminate structures with non-sealable outer layers (e.g., PET, OPP). | Limited. Requires films where both the inner and outer surfaces are heat-sealable, such as monolayer polyethylene (PE) or co-extruded films. |

| Seal Appearance | A protruding fin, which is typically folded down. May interrupt graphics on the back panel of the bags. | Flat and smooth. Offers a sleek appearance with uninterrupted graphics, which can be a customer’s desire for retail-facing consumer goods. |

| Production Speed | It can be slightly slower due to the mechanics of folding the fin. | Potentially faster due to a simpler sealing action. However, speed is often dictated by other machine and product factors. |

| Typical Cost | Higher material cost due to wider film. The sealing jaws may also have a more complex design. | Lower material cost due to reduced film consumption. This is a primary driver for its adoption in suitable applications. |

Material Compatibility: How Film Type Affects Seal Performance

While the table above outlines several key distinctions, one factor—material compatibility—often serves as the primary, non-negotiable determinant in the selection process. The structure of the packaging film itself will frequently dictate which sealing method is not just preferable, but technically feasible. This section delves deeper into why the film is the most decisive element.

Fin seals are the required choice for multi-layer laminated films. These materials are performance-based and may be based on a combination of various layers to produce certain barrier characteristics, durability, and printability. One of them would be Polyester (PET) / Aluminum Foil (AL) / Polyethylene (PE). The outer PET layer will give a high-quality print surface and strength, the foil will offer an excellent barrier to oxygen and moisture, and the inner PE will act as the sealant in this case. The inner PE layer cannot be closed to the outer PET layer, and therefore lap seal is impossible. The only alternative is the fin seal, which only allows the PE sealant layer to adhere to itself, hence seal integrity and exclusion of external factors to the product. This renders it the standard in high-barrier food packaging, pet food, and most bioscience applications.

Lap seals are best suited for monolayer or specific co-extruded films. Lap seals work best with monolayer films or certain co-extruded films. Monolayer films are made of a single polymer, like Low-Density Polyethylene (LDPE), having identical surfaces. Although co-extruded films can also be designed for lap seals. Co-extruded films are created by simultaneously extruding several layers of different polymers to form a single integrated film. If the film is designed with a heat-sealable layer on both the inside and the outside, lap seal packaging becomes a highly efficient option that protects the contents from external elements. This film is typically meant for items where a hermetic seal is not critical or where a seal is not as important as saving raw material costs, like the wrappers for some magazines or baked goods. If a lap seal is used with an incompatible film, the seal will fail and the film will be damaged, and the product will be wasted. This will lead to possible injury during shipment.

Industry Applications: Where Each Seal Type Excels

Material science is a critical element in determining the various market applications for each seal. Different films are influenced by certain technologies, which form the basis for the adoption in specific industries. Each industry takes advantage of the specific attributes of either the fin or the lap seal. These applications provide a real-world contrast to theoretical concepts.

Fin Seal Applications:

The fin seal is the best choice for seals on packaging that demand the highest levels of security and feature products with long shelf lives. These packages require strong and durable seals to maintain seal integrity.

Food Products: Depending on the packaging type, the fin seal is used in a large variety of food packaging, especially for items sensitive to oxygen, moisture, or contamination. These include closed packaging for snack foods (potato chips), coffee, powdered mixes, and frozen foods. The seal helps maintain the product in terms of safety and freshness.

Pharmaceuticals & Medical: Fin seals provide high-integrity enclosed spaces for medical devices and sealed packs for pharmaceutical products, where spillage, sterility, and barrier protection are priorities.

Industrial and Chemical: Laminated films are used for packaging industrial and chemical products, such as powders and liquids, sealed to stop spills and ensure the safety of the product.

Lap Seal Applications:

Lap seals are perfect for high-volume applications where the reduction of material costs is the main focus and the barrier properties are not a priority.

Confectionery: Candy bars, crackers, and biscuits are favorite snacks that are frequently packaged using a lap seal. They create a sleek appearance for full panel branding, and material savings are significant at high production volumes.

Bakery: Some simple PE film packaged, fresh bakery items with a short shelf life also utilize a lap seal for economical and adequate sealing.

Non-Food Consumer Goods: Classic lap seal packaged consumer items, such as wrapped soap bars, trading cards, and magazines, illustrate the use of this seal. It contains and protects items from dust and does not require a hermetic barrier.

Choosing the Right Seal: A Practical Decision Framework

Choosing the right flexible packaging materials and sealing technique for your application requires a systematic and functional approach to address appropriate packaging applications that would be the best fit for your needs. Use this four-step system to guide your decision and ensure that your needs are thoroughly analyzed.

- ● Step 1: Analyze Your Film Structure.

This is the foundational step. Identify the composition of your film. Is it a monolayer homopolymer, a co-extruded film, or a multi-layer laminate? If the outer layer is not a sealant, a fin seal is your only option. If both surfaces are sealable, you can proceed with the evaluation of a lap seal.

- ● Step 2: Define Your Barrier & Strength Needs.

Evaluate the requirements of your product. Does it require a hermetic seal to protect against oxygen or moisture and maximize shelf life? Is a high level of puncture resistance or drop protection necessary? If the answer is yes to any of these, the higher seal strength of a fin seal is strongly recommended.

- ● Step 3: Evaluate Aesthetic and Branding Goals.

Evaluate the package design. Is a clean, uninterrupted back panel critical for your branding or regulatory information? A lap seal provides a smoother, more premium look. If the back panel design can accommodate a folded-over fin without compromising key visual elements, then a fin seal remains a viable option.

- ● Step 4: Calculate the Long-Term Cost Impact.

Concluding a choice typically requires a trade-off between performance and cost. Estimate the savings associated with the reduced materials of a lap seal based on your yearly film consumption. Consider the savings in conjunction with risks such as higher seal failure rates, less protection to the product, and product waste. Reduced lap seals are also preferable, given the global emphasis on sustainable packaging.

From Seal Selection to Full Packaging Excellence with Baishen Pack

Choosing a fin seal or a lap seal is only a minimal part of successful packaging. Real success is based on the film structure, sealing accuracy, and the craft of production.

At Baishen Pack, we pay full attention to these components in every assignment and provide custom-engineered flexible packaging designed to match the product’s material, barrier requirements, and brand. Our domestic staff determines the optimal seal type, material blend, and finish to provide a satisfactory combination concerning protection, efficiency, and aesthetic charm.

Whether it’s packaging snacks and pet food or packaging coffee, Baishen Pack transforms technology into precise packaging that is functional and protects the brand.

Common Sealing Problems and How to Troubleshoot

Successful packaging operations begin with selecting the right seals. However, proper execution is just as important. Even the most ideal choice can fail because of operational breakdowns, so understanding how to identify and resolve malfunctioning seals is equally critical for planning the production flow and matrix of quality control for the production line.

| Problem | Possible Cause | Solution |

| Weak or Incomplete Seal | Insufficient heat, dwell time, or pressure. Worn or dirty seal bars. Misalignment of the film edges or sealing jaws. | Increase temperature, dwell time, or pressure incrementally. Clean or replace seal bars. Verify alignment of the forming tube and sealing mechanism. |

| Wrinkled or Puckered Seal | Excessive heat or pressure. Uneven film tension as it enters the sealing area. | Reduce temperature or pressure. Check and adjust the film unwind tension and rollers to ensure a smooth, even feed. |

| Film Burn-Through | The temperature is too high for the film type or gauge. Dwell time is too long. | Immediately reduce the sealing temperature. Decrease the dwell time. Confirm that the film specifications match the machine settings. |

| Product in the Seal Area | Poor timing between product drop and jaw closure. The product creates dust that contaminates the sealant layers. | Adjust machine timing to allow the product to settle before the seal is made. Install a dust collection system or use specialized jaws designed for dusty products. |

| Channel Leaks in Seal | A small wrinkle or fold that runs the length of the seal, creating a microscopic channel. Often caused by misalignment or improper forming. | Inspect the forming collar and tube for damage or misalignment. Ensure the film is tracking perfectly straight. For a fin seal, ensure the fin is folded properly. |

FAQs About Fin Seal vs Lap Seal

What are the different types of sealing bars?

There are smooth and serrated jaws. The use of serrated jaws concentrates and increases pressure in specific areas, assisting in pushing out any possible contaminants and sealing the area. The configuration of serrations used (horizontal, vertical, or cross-hatch) changes seal quality in different ways.

What is a fin seal bag?

In flexible packaging, a fin seal bag refers to any bag, like a pillow pouch or a gusseted bag, which uses a fin seal on the primary vertical seam. This is very common in the snack food industry.

What does seal packaging mean?

Seal packaging means protecting a package by sealing it shut. It concerns sealing techniques used in flexible packaging, which typically employs heat sealing where layers of thermoplastic film are bonded together.

What’s stronger: a fin seal or a lap seal?

Yes, a fin seal is stronger. It forms a more durable bond by joining two identical specialized sealant layers, whereas a lap seal bonds a less specialized outer layer to an inner sealant layer, which is more weakly bonded.

Which is more cost-effective?

From a material cost perspective, a lap seal is more cost-effective as it utilizes less film. However, the total cost-effectiveness of a lap seal is dependent on the application. If a lap seal results in excessive spoilage, the material cost benefits become irrelevant.

Can both seals be used on the same packaging line?

Yes, but it entails a changeover. VFFS and HFFS machines are both customizable to either seal type. The changeover involves changing the forming tube and possibly sealing jaws. This required change adds complexity to the production schedule as well as time.

Conclusion

In packaging consumer and industrial goods, the decision to select either a fin seal or a lap seal, or any type of seal, is a complex choice that spans both engineering and business spheres. It is never a case of one option being better than the other. It is simply which option is the best for the particular combination of the product, packaging film, and operational priorities.

In applications where protection of the product and seal integrity are critical, the standard is the fin seal, which offers seamlessness, dependable performance, and extreme versatility across materials. The lap seal, however, has a distinctive economic edge due to large savings on materials, and even fulfills the aesthetic requirement of finishing costs, especially for products that are less barrier stringent and cost sensitive.

By evaluating the packaging materials to be used, along with product protection, branding, and overall costs, the packaging professional can choose the seal that provides the best combination of performance, cost-effectiveness, and value for the chosen application. This is necessary for successful flexible packaging.