Picture this: you have finished a bag of your favorite chips, enjoyed the salty goodness, and you are left with a shiny, crinkly empty bag. You start to wonder, should this go in the trash or the recycling? The packaging looks like plastic and has that familiar recycling symbol, but something feels off. This small dilemma poses a larger question: what do we do with flexible packaging, which is extremely common in today’s society?

This will help you to get an understanding of the topic. We will help you understand why chip bags are not recyclable, what happens to your trash, and what materials are starting to change packaging for the better.

The Quick Answer: Why Chip Bags Can’t Be Recycled

Let us be direct: No, chip bags are not recyclable through your standard municipal curbside recycling program.

When you put a bag of chips in your mixed bag, it will not get recycled. At best, it will be sorted at the recycling plant and end up in a garbage landfill. At worst, it will either create contamination with other useful recyclables or destroy sorting equipment, which can lead to the rejection of a whole batch of materials.

The essence of this rejection lies in the writing of the material. Their bags are not just plain plastic bags but advanced engineering technology components consisting of a blend of various and diverse materials. Traditional recycling systems can separate and recycle single-material streams, e.g., glass bottles, aluminum cans, or #1 (PET) plastic bottles.

A chip bag is an unrecoverable pollutant in this system due to its mixed nature, made of different materials. Thus, it is the right thing to do in regard to your local recycling process to put these bags in your general waste bin so that they do not create a detriment to the recycling stream. This is, however, not the end of the story as we will see.

Science: What Are Chip Bags Actually Made Of?

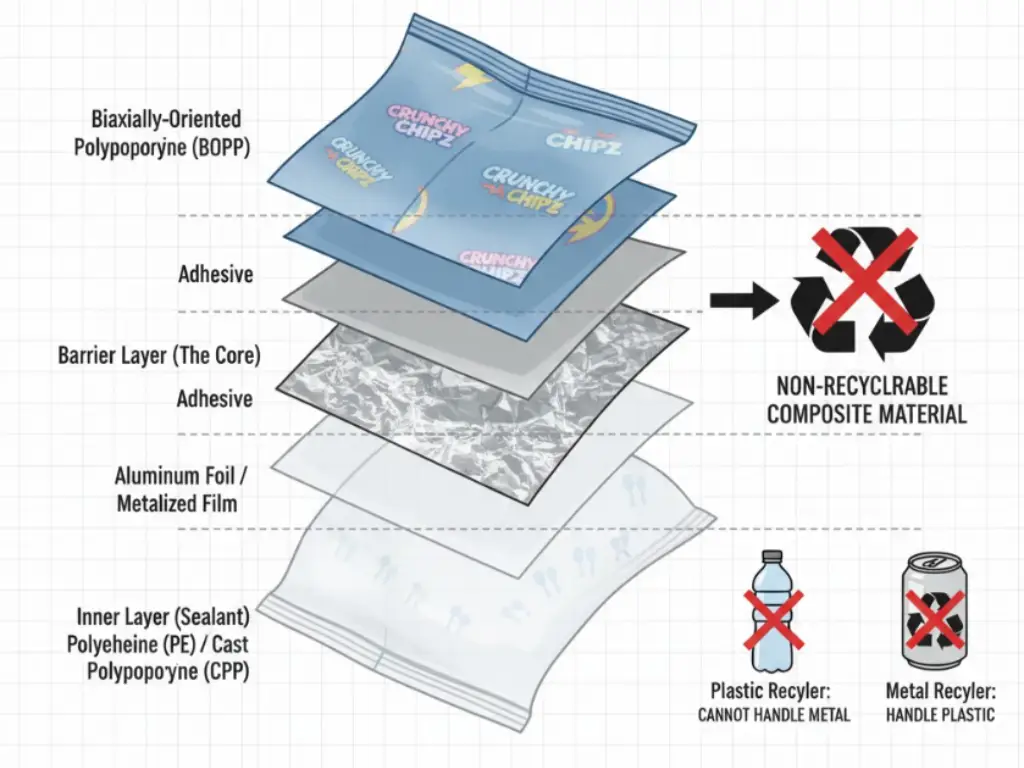

To understand why chip bags cannot be recycled, we must first understand what they are. The average snack bag is a technical marvel known in the packaging industry as a “multi-layer laminate” or “flexible barrier packaging.”

It is not one material but a composite, typically involving three or more layers laminated together with adhesives and heat. If you could peel apart a chip bag, you would find distinct layers, each serving a specific purpose:

| Layer | Common Material | Primary Purpose |

| Outer Layer | Biaxially-Oriented Polypropylene (BOPP) | Provides stiffness and a high-quality, durable surface for printing brand graphics. |

| Barrier Layer | Aluminum Foil (or Metalized Film) | The most critical layer. It blocks oxygen, moisture, and light to keep the product fresh. |

| Inner Layer | Polyethylene (PE) or Cast Polypropylene (CPP) | This food-safe layer acts as the sealant, allowing the bag to be heat-sealed closed. |

These layers are not designed to be separated. They are bonded together to create a single, high-performance plastic film. This fusion is precisely what makes standard plastic recycling impossible. A facility designed to recycle #5 plastic (Polypropylene) cannot handle the aluminum, and an aluminum facility cannot handle the plastic. The materials are, for all practical purposes, permanently co-mingled.

Why Brands Use This Packaging: The Freshness vs. Waste Dilemma

Some might argue this type of packaging is a waste of resources, but it does provide a solution to a pressing challenge in food science. There’s a reason brands utilize it: barrier properties.

Chips are at risk of deteriorating in two ways:

- ● Oxidation: Chips contain oils and fats, which will go rancid once exposed to air, causing off-flavors and odors.

- ● Moisture: Chips are hygroscopic and will absorb moisture from the air. Even the smallest amount of water will make a chip stale, leathery, and unpleasant.

The hero of freshness is the thin layer of aluminum foil. It offers an almost ideal oxygen (Oxygen Transmission Rate, or OTR) and water vapor (Moisture Vapor Transmission Rate, or MVTR) barrier. It also prevents light, which may hasten fat degradation.

This presents the biggest challenge in the industry. The packaging that offers the highest level of food safety and prolongs the shelf life of food to reduce waste is the same packaging that creates a problem with end-of-life recycling. The goal is to reduce waste while continuing to maintain food freshness.

Why Chip Bags Contaminate Your Recycling Bin

Once a non-recyclable product, such as a chip bag, is taken to a Material Recovery Facility (MRF), it results in a contaminant that produces two major and expensive issues.

The first problem is that of sorting. The high-speed sequence of automated technologies employed by MRFs is used to divide materials. The products on a conveyor belt are scanned using optical sorters, which detect the type of plastic (such as PET #1 and HDPE #2) and project the same onto different tracks using air jets. A pack of cigarettes distracts this system. The scanner may view the plastic outer cover and consider it to be plastic, or it may view the inner metal cover and consider it to be metal. In both situations, it is not the picture of a clean, single-stream material and is normally rejected and sent to the landfill pile.

The second problem is mechanics. Chip bags are made of plastic film, which falls under the category of plastic film, including grocery bags, bread bags, and bubble wrap. These materials represent the greatest adversary of rotating machines within an MRF.

MRFs employ huge and rotating screens (disc screens) to separate two-dimensional materials (such as paper) and three-dimensional materials (such as bottles and cans). Fine, plastic film is not like either. It coils itself around the axles and gears of this sorting gear, just as does the hair in a vacuum cleaner. This causes the whole plant to close down- many times a day- and the employees to reach inside the machine with utility knives to scrape the wrenched film away. This is dangerous and expensive, and is a key reason why contaminated plastic film bins are a huge problem.

How to Actually Recycle Chip Bags (The Right Way)

Although you cannot use your curbside bin, specialized programs do exist, the most prominent and widely available being TerraCycle. They can accept hard-to-recycle items like used snack wrappers, as well as other items in the recycling collection stream. TerraCycle is a private company that has partnered with brands to provide recycling and collection solutions for previously unrecyclable items like coffee capsules.

Here is the actionable, step-by-step process:

Brand Programs. Visit the TerraCycle website to see if any programs handle snack bags or chip bags. Nationally, free programs are often sponsored by popular brands, like Frito-Lay (PepsiCo). You register for the program, gather the designated waste materials, and when your box is full, print a shipping label and send it in at no charge.

Zero Waste Box. If there are no free programs, a “Snack & Candy Wrappers” Zero Waste Box can be purchased. You’ll pay for the box and send the wrappers back (shipping is included in the price). This is a paid solution. Offices, schools, and very devoted households tend to purchase this option to meet their waste disposal goals.

How TerraCycle Processes Them. The first step is to separate the waste materials. The bags are usually shredded, washed, and turned into plastic pellets. Instead of becoming contaminants in the landfill, the plastic pellets are converted into useful and durable products, such as park benches, shipping pallets, and outdoor decking.

This is the only legitimate recycling option that exists today for this type of composite packaging.

Creative Upcycling Ideas (Beyond the Bin)

If you happen to thrive creatively or in the world of DIYs, “upcycling” offers one more way to not send chip bags to waste. Upcycling refers to reusing a waste material in its current form, while creating a new item of equal or greater value. Plastic films are of high quality, durable, waterproof, and, nevertheless, quite versatile as crafting materials.

Fused Plastic “Fabric”: By layering several clean, dry bags between two parchment paper sheets, you can melt and fuse them using a household iron on low. This creates a strong, durable, and waterproof “fabric” that can be sewn into zippered pouches, wallets, or reusable tote bags.

Woven Accessories: The bags can be cut into uniform strips and looped together to create “plarn”, or plastic yarn. This yarn can be crocheted or knitted to create sturdy tote bags, placemats, or coasters.

Gift Wrap and Decorations: Colorful and branded bags can be used as gift wrappers to replace traditional gift wrapping paper. They can be cut into strips to create festive garlands or bows.

The Future: How Brands Are Solving This Problem

While upcycling and consumer-focused initiatives like TerraCycle are helpful, lasting change needs to come from the industry itself. The most efficient evolution is to eliminate packaging waste by redesigning packaging.

Leading snack food manufacturers have started to take steps to shrink their packaging waste. PepsiCo, the parent company of Frito-Lay, has committed to making all of its packaging recyclable, compostable, or biodegradable by 2025 or 2030. To achieve these goals, many of these companies are investing in next-generation materials like mono-material pouches.

A mono-material pouch is constructed from one kind of plastic, either 100% polyethylene or 100% polypropylene. The difficulty is replacing the high-barrier performance of aluminum while keeping the pouch recyclability. New materials like EVOH (Ethylene-vinyl alcohol) and other barrier layers and specialized coatings are helping solve this packaging engineering challenge.

While these mono-material pouches are not curbside recyclable, they are recyclable under store drop-off recycling programs for plastic films. As mono-material technology improves, it offers great potential for a sustainable and circular flexible packaging system.

How to Spot “Recyclable-Ready” Flexible Packaging

You can already see the beginnings of this shift toward sustainability on the shelves. Shoppers can easily spot new packages with the labels “Store Drop-Off Recyclable,” “Mono-Material,” or “100% PE Pouch.” The indication changes from problematic multi-material composites. These packages can be recycled, albeit through store drop-off bins.

Food and snack brands face the challenge of figuring out how to innovate “recyclable-ready” packaging. It requires a new approach to packaging design, particularly moving away from the non-recyclable multi-layer packaging made of plastic and aluminum, to a new mono-material packaging. The new packaging must also meet the required product protection from moisture and oxygen, a high-barrier packaging demand.

That being said, it is certainly not a simple process and requires not only resource investment but also sophisticated packaging engineering. This is where a specialized manufacturer of complex packaging becomes a key partner.

Having provided global packaging supply and support for over 10 years, Baishen Pack is the industry’s go-to expert for design transitions for brands in the food, snack, and pet food sectors. Our focus is on:

- ● Innovative Packaging: Our specialized engineering team designed high-barrier mono-material films to serve as core packaging for recyclable, bio-based, and compostable.

- ● Expert Engineering: Our seasoned packaging engineers make certain that these new materials provide strong, high-barrier performance. We aid clients in maintaining their product’s freshness and shelf life, thus ending the trade-off between sustainability and product safety.

From start to finish, we collaborate with clients to create and produce these advanced solutions.

If your brand is prepared to make the transition to quality sustainable packaging, reach out to the Baishen Pack engineering team to discover our recyclable, high-barrier options.

Conclusion

Are chip bags recyclable? The answer is:

- ● No, they are not recyclable in your curbside recycling bin, where they are a harmful contaminant.

- ● Yes, they are recyclable through specialized mail-in programs, like TerraCycle, which downcycles them into new products.

- ● Soon, the industry will transition to new “recyclable-ready” mono-material designs that will be compatible with store drop-off plastic bag recycling programs.

Currently, the consumer has two responsibilities: first, keeping these bags away from the municipal recycling stream, and second, using an alternative like TerraCycle or throwing them in the general waste. In the future, the real answer will be manufacturing innovation, where businesses rethink packaging and design it to be a resource, not a waste item.