In the current dynamic market, brands have to be dynamic and very relevant to consumers. The packaging of your product is no longer a container; it usually represents the first physical experience a customer has with your brand, and as such, the packaging is a highly important brand touchpoint and a visual representation of brand promise. The rules of packaging were governed by traditional analog printing methods that were based on mass production a long time ago. This has changed with the entry of digital printing.

Digital printing is not merely a new process of production. It is a driver that changes the way brands can meet the market, shatters the traditional barriers to entry, remakes the slow supply chain into a dynamic asset, and static packaging into a dynamic data-driven tool. Brand managers, startup founders, and marketing strategists should no longer be left wondering about the strategic importance of using digital printing to print packaging materials, because it is a survival and growth requirement. This primer will give a logical outline, taking the reader through strategic reasoning and practical application.

The Benefits of Digital Printing for Packaging

The real effect of digital printing is not the ink and the substrate only. This technology transforms the strategic approach of brands essentially. Offset and flexography are traditional techniques that need immense volumes to achieve costs that are comparable to digital printing, which flourishes in nimbleness and diversity. It is not a mere step change but a paradigm shift, which reinvents the fundamental business practices.

- ● Minimization of Market Risk

Traditionally, launching a new product or testing seasonal packaging required a large upfront investment—often tens of thousands of units—turning innovation into a high-stakes gamble. If a product failed, brands were left with unusable inventory and environmental waste. Digital printing flips this model. Economical short runs of 500 or 1,000 units enable real-world testing, feedback collection, and iteration. This launch-measure-learn loop, common in software, now applies to physical goods, dramatically reducing innovation risk and accelerating product-market fit.

- ● Re-engineering Supply Chain Speed

Conventional packaging requires months of lead time, during which demand must be predicted with limited accuracy. The result: stockouts or costly overstocks. Digital printing eliminates the need for printing plates and lengthy setups, slashing production timelines from months to weeks or even days. This enables just-in-time inventory practices, freeing up capital and storage space. Brands can now respond quickly to demand surges or competitor actions with unprecedented agility.

- ● Transformation of Marketing through Personalization

Packaging is not dead anymore, and it is an active and data-driven marketing tool. Using Variable Data Printing (VDP), each package can be individual: it can have the name of a customer, personal offers, QR codes to custom landing pages, or geographically or demographically tailored art. Packaging has now been able to interact with the consumer at the most important point of unboxing, creating one-to-one interaction that helps to reinforce brand relevance and loyalty.

- ● Strengthening Sustainable Practices

Traditional printing means there is always overprinting, outdated stock, and a lot of wastage of materials. Digital printing enables the manufacture of precise, on-demand production-“print what you want, when you want it.” This cuts down environmental waste since there is less waste and no need to dispose of old packaging. Not only does sustainability become an ethical necessity, but also a business benefit as efficiency and responsibility go hand in hand.

- ● Driving Cross-functional Collaboration and Agile Decision-making

The speed and flexibility of digital printing reshape internal brand workflows. Marketing departments can use real-time adjustments to packaging to match a promotion or a social trend. In the meantime, supply chain managers can change the production cadence to prevent the overstock or understock situation. This creates closer coordination amongst product development, marketing, and operations, which facilitates a quicker and richer decision-making cycle and a more responsive and future-proof organization.

Digital Printing Packaging vs. Traditional: Making the Right Choice

The choice of a printing method is a strategic choice, which makes technology match the volume, timing, budgets, and customization requirements of your project. It is important to comprehend the unique strengths of digital, offset, flexography, and gravure.

Traditional methods such as Offset, Flexo, and Gravure are designed to work on large volume production. Plates or cylinders are costly and time-consuming. They are inappropriate in small quantities, although their costs per unit are very low, in extremely large runs.

Digital printing, however, works directly from a digital file to the material, cutting out plate costs. This eliminates large costs of setup and long lead times and works only in short runs, high variability, and quick turnaround.

This is the breakdown of the major decision factors comparison:

| Feature | Digital Printing | Offset Printing | Flexographic Printing | Gravure Printing |

| Setup Cost | Very Low / None | High | High | Very High |

| Per-Unit Cost (Short Run) | Low | Prohibitively High | High | Prohibitively High |

| Per-Unit Cost (Long Run) | High | Very Low | Low | Extremely Low |

| Turnaround Time | Fast (Days to Weeks) | Slow (Weeks to Months) | Moderate (Weeks to Months) | Very Slow (due to cylinder engraving) |

| Variable Data | Excellent (Every unit is unique) | Not Possible | Not Possible | Not Possible |

| Ideal Volume | 1 – 10,000 units | 10,000+ units | 5,000+ units | 100,000+ units (very long runs) |

| Color Matching | Excellent, highly consistent | Excellent, Pantone standard | Good to Excellent | Excellent, vibrant, highly consistent |

| Proofing | Fast, inexpensive (digital & hard copy) | Slow, costly (press proofs) | Slow, costly (press proofs) | Very Slow, costly (press proofs) |

| Substrates | Paperboard, Corrugated, Flexible Films | Paperboard, Corrugated (pre-print), Labels | Flexible Films, Labels, Corrugated (post-print) | Flexible Films, Laminates, High-end paperboard |

| Print Quality | Excellent, photo-realistic | Excellent, fine detail, smooth tones | Good to Excellent | Superior, rich, vibrant colors, fine detail |

The Decision Checklist: When to Choose Digital

Go through this checklist to see whether digital printing is the best option to tackle your project.

- ● You do not have more than 10,000 units.

- ● Time-to-market is essential.

- ● You require several design variations (SKUs) within one run.

- ● One of the objectives is personalized packaging for market campaigns.

- ● You are entering a new market or product, in which you have to de-risk.

- ● One of the main goals is a reduction in inventory and waste.

- ● You prioritize precise, consistent color on short runs.

Calculating Your True Cost and ROI

The pricing of printing processes by the unit price is a fatal error. Although printing runs may be perceived to be cheaper per unit when dealing with large quantities in traditional printing, the analysis is still incomplete. With a Total Cost of Ownership (TCO) model, brands are required to uncover the true financial image.

TCO covers everything, including the costs that are obscure in conventional printing:

- ● Unit Price: The cost quoted per piece.

- ● Set Up Costs: High in traditional (plates, press set up, gravure cylinders), virtually non-existent in digital.

- ● Inventory Costs: Costs of storage, management, and insurance of large run prints. The on-demand production of digital cuts down these drastically.

- ● Obsolescence Costs: the most ignored cost. Any packaging that is not used as a result of market turnover or termination of a product leads to total loss. This is reduced by the short runs of digital.

TCO Formula:

- TCO=Unit Price+Setup Costs+Inventory Costs+Obsolescence Costs

Digital printing produces new value that goes beyond simple savings and that has a direct effect on your Return on Investment (ROI). This new value is the other benefits and sources of revenue that digital printing opens up to your business, not just the price of printing.

ROI Formula:

- ROI = (New Value Created- Cost of Investment) / Cost of Investment

Here’s what that “New Value Created” means for your business:

- ● Increased Sales: Digital lets you package the product in a personalized way, such as different names or offers that increase the likelihood of purchase by the customer. This has a direct increase in your sales revenue.

- ● Better Brand: You can easily come up with limited editions or special designs. This creates anticipation and brand loyalty such that your brand becomes more and more valuable as time goes by.

- ● Quick to Market: Digital is faster, so you can introduce new products or promotions at a much faster rate. It is also more likely that the ones who come first take advantage of more market share and sales.

- ● Valuable Customer Data: Packaging with special QR codes can deliver customers to online materials. This will allow you to gather valuable information concerning their preferences, which will enable you to market more smartly and develop superior products.

The financial case of digital printing is obvious after evaluating the costs in terms of TCO and evaluating the value in terms of strategic ROI. A lower sticker price in particular situations is not the point; it is a smarter and more nimble business strategy that ends up being more profitable.

From Design File to Finished Product

There are several important steps in making your packaging design a physical, digitally printed product. Knowing the process, you can make sure that the work process will run fine and the final outcome will fit your vision perfectly.

1. Design and File Preparation

The first thing you should do is to complete the structure of your packaging. This is characterized by a dieline-flat pattern displaying all the points of cut, crease, and assembly. You may select a template of standard design, or you may design with your printer a custom shape.

Then make your art. These are important details to watch out for:

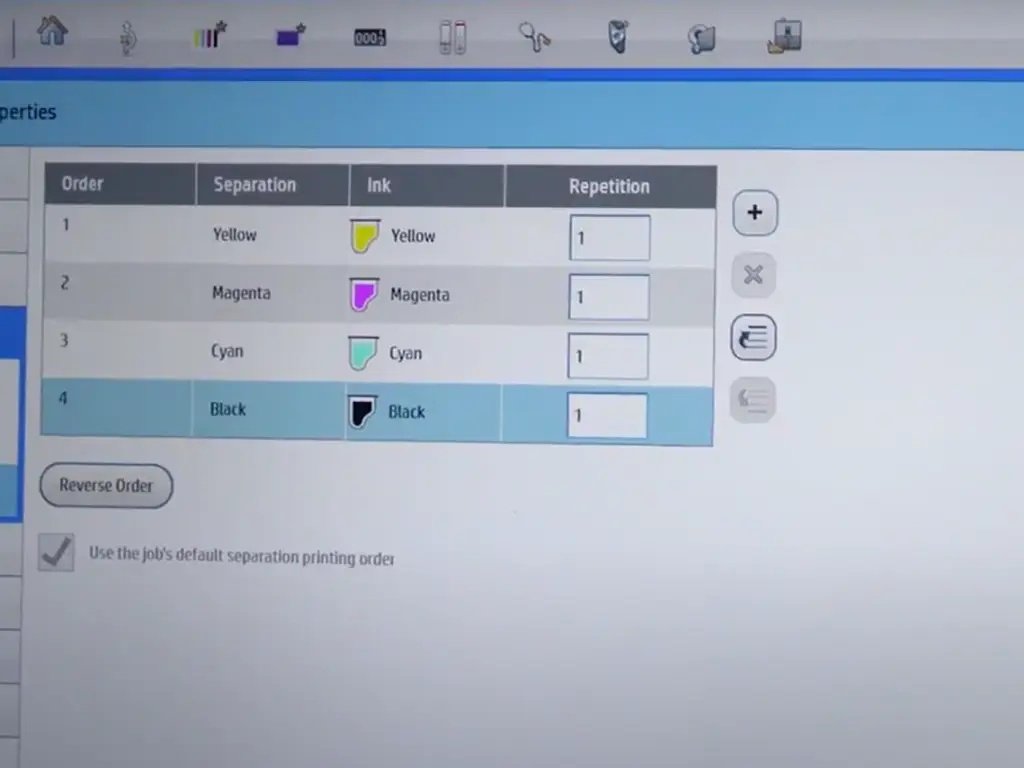

- ● Color Mode: Design in CMYK all the time. RGB (used on the screens) will create color changes when printed.

- ● Image Resolution: Photos, or any other raster images: make sure that there is a minimum of 300 DPI (dots per inch) at the final print size to avoid pixelation.

- ● Graphics Type: Vector graphics are to be used on logos and text. They can be blown up to any size without dulling.

- ● Bleed and Safe Zone: This is where you extend your background design onto your paper by approximately 3mm (1/8th inch) past the cut lines (the bleed). This will avoid white edges when the cut is not exactly precise. Also, it is necessary to keep all the important text and graphics in a safe zone inside the cut lines so as not to be lost in the cuts.

2. Material Selection and Proofing

Select the proper material according to the purpose and feel of your packaging. They can be made of paperboard, corrugated cardboard (box), films of different types (bags, pouches), or adhesive stocks (labels).

Never go to mass production without proof. This is your final chance to catch errors.

- ● Digital Proof (PDF): You can use it to verify layout and text position. It cannot be depended upon to match colors accurately.

- ● Physical Evidence (Hard Copy): It is a real, made-up sample printed on your preferred material. It is needed to check the real color, the texture of the material, and the structural strength. Only approve once you’re 100% satisfied.

3. Production and Finishing

After you authorize the proof, your work makes it over to the digital press. It will print your design on the material of your choice. The material then is cut, creased, folded, glued (in the case of boxes), wound, slit, and bagged (in the case of flexible packaging and labels) depending on the product, and it becomes your finished packaging product. You also have the option of adding different enhancements, such as lamination (matte or gloss) or spot varnishes, to give extra durability and visual attractiveness.

Innovations: Smart and Sustainable Packaging

Digital printing is a moving force in changing the face of innovation in packaging, especially in two major dimensions, sustainability and smart packaging solutions.

Digital printing contributes a lot to the environmental profile of packaging. It reduces waste at the source of production by removing the requirement to use plates and minimizing waste during setup. Its on-demand feature is vital in terms of minimizing obsolescence because brands print what is required, and the remaining inventory can be drastically reduced, which goes to the landfills. Moreover, the digital presses are becoming more compatible and better at performing on recycled, post-consumer waste, and certified sustainable stocks of paper, enabling brands to combine environmentally conscious practices with the use of eco-friendly material.

In addition to the static aesthetics, digital printing will allow so-called smart packaging, increased consumer interaction, and supply chain smartness. The variable data printing (VDP) allows every package to be different, enabling hyper-personalization of the type of custom messages or promotions that are regionally specific. It can also assist in improved traceability in supply chains where unique, individualized codes (such as QR codes) can be printed on each unit, providing visibility and authentication of products that have never been seen before. These unique identifiers turn packaging into an interactive channel of marketing and can direct consumers to augmented reality, product tutorials, personalized offers, or direct feedback platforms. This changes the package to a living portal of continuous brand-consumer communication.

Choosing the Right Digital Printing Flexible Packaging Partner

Your partner on the digital packaging project must have the capabilities to make your project successful. Technology is as good as a team. In the selection of potential suppliers, do not concentrate only on the price; one should pose specific questions to determine their effectiveness.

This is a key list you should use to make the right choices:

- ● Technology & Quality: Ask them what their main digital printing technology is (e.g., HP Indigo, high-speed Inkjet). By understanding their technology, you gain the agility to request samples of similar work on the material, to see the quality of print and color.

- ● Materials & Finishes: Ensure that they supply the substrates (e.g., paperboard, films) and finishing (e.g., lamination or spot gloss) according to the needs of your brand.

- ● Proofing Process: Get to know how they usually proofread, particularly their attitude towards hard copy (physical) proofs. This is something that a trusted partner will insist on for new projects so that you can be satisfied with the color and the way the material feels.

- ● Consistency of color: What is their process of color management, i.e., press calibration, and how do they guarantee reorders of the same color even 5 years later?

- ● File Preparation & Data Security: Their data security should give clear file preparation guidelines. In case your project deals with variable data, make sure that their data security is strong.

- ● Minimums & Pricing: Know their Minimum Order Quantity (MOQ) and pricing as it applies to quantities.

An actual printing partner is a consultant and can give you good advice on material, layout, and cost-saving ideas.

.webp)

Baishen: Your Partner for Digital Flexible Packaging Pouches

Baishen has unique strengths in providing experienced and highly versatile companies in digital flexible packaging pouches, especially to brands. Having more than 10 years of experience in the packaging bag industry, we offer a genuine one-stop shop with innovative packaging solutions, design, digital printing, laminating, slitting, and bag production. We have a group of dedicated people who are professional sales personnel and creative designers, and together we work with you in giving you customized solutions and eye-catching designs that can take your product to a new level. Using state-of-the-art HP Indigo digital presses, we can provide high-resolution printing, which has 97% Pantone colour matching and can run mixed SKU jobs, which guarantees both quality and efficiency. Added to our competitive factory-direct prices and our 7-10 working day digital turnaround time, it means that your high-quality, food-grade packaging bags can be manufactured in a hurry, at a low price, and with total quality control over the raw material sourcing process through to the finished, long-lasting and leak-free product.

Are you ready to innovate your packaging with a well-known partner? Contact Baishen today to discuss your digital flexible packaging requirements and get an individual quote.

Common Mistakes to Avoid

Digital packaging is an empowering experience for the brand; nevertheless, there are a number of pitfalls that are likely to derail a project. Knowing about them beforehand saves time, money, and frustration.

- ● False Cost Comparisons: One of the most common mistakes is that the cost of a high volume print run (traditional) is compared to a low volume print run (digital) without regard to the Total Cost of Ownership (TCO). Waste, inventories, and setup costs should be taken into consideration at all times.

- ● Designing in isolation: You may have a nice, intricate design in mind, but without first consulting your printer, you may have a problem. A digital press might not accurately reproduce colors (or gradients) in the same way as a screen. Consider the end substrate when designing because the material will have a big effect on the appearance of the color.

- ● Underutilizing Technology: A complex digital press is not the best machine to use on a simple, static, large-volume job. In most cases, such a project is cheaper to print using a conventional form of printing.

- ● Skipping the Proofing Step: The temptation to rush to the market might tempt the brands into skipping the step and approving a project on the basis of a PDF proof. Nevertheless, the color and the material feel can only be properly checked utilizing a physical sample. Never wait without a hard copy proof.

- ● Poor File Preparation: Some of the many technical issues are sending a low-resolution image, wrong color mode (RGB rather than CMYK), or lack of bleed. Such errors lead to low production and poor outcomes.

By preventing such mistakes, you will be able to take full advantage of digital printing and have a direct route between an idea and a marketable product that is successful.

Conclusion

Digital printing is not merely a technical process; it is a strategic requirement in contemporary brands. It is a direct response to the need for speed, personalization, sustainability, and authenticity in the market. Digital printing can turn packaging into a high-growth driver by allowing brands to de-risk innovation, create nimble supply chains, and create a direct, interactive relationship with consumers that, in turn, underpins sustainable growth. The choice is not anymore on how to print a product container; it is on establishing a resilient and relevant brand for the future.